A 1963 (1964?) Ducati Diana Mark III 250 came through the shop a while back. It was partially restored, and needed to have the last bit of the job done. The bike was owned at one point by Jason Small, who also painted it. During the research and restoration, some of the information suggested it was a Mark III model, a US version imported by Berliner with a competition set-up. With that in mind, it was modeled as closely to the specs of the original, with the exception of the muffler.

Classic Ducati styling from a great era of motorcycle styling and building. Touted as a ready to race factory model, The Mark III was stripped down, and fitted with performance parts. A larger competition type Dell Orto carb and velocity stack, twin tank petcock feeds, free flowing exhaust, and other mods produced a reported 30 horsepower from the 250cc engine! The competition tachometer, clip-on handlebars, passenger peg delete, and battery-less ignition rounded out the package. Items found on other Diana models like side covers, air, tool, and battery boxes were also stripped off to save weight.

Even the tail light was kept small to minimize weight, but still satisfy racing categories that require stock unmodified bikes.

The front number plate/windscreen showed up in the Berliner advertisements, but it is unclear if this was a factory part. This one was made from aluminum and Lexan, and modeled from the Berliner brochure images.

The bike as I found it. Paint had been done, but a bunch of parts were missing, and the everything needed cleaning and detailing.

The engine was loosely bolted in, and in need of some work, but was said to be in running condition prior to tear-down.

After replacing and re-plating hardware, some cleaning and polishing and a bunch of new parts, the beauty of this Ducati design shines through.

A badly worn seat came with the bike, but did not fit properly, and did not resemble the original seat.

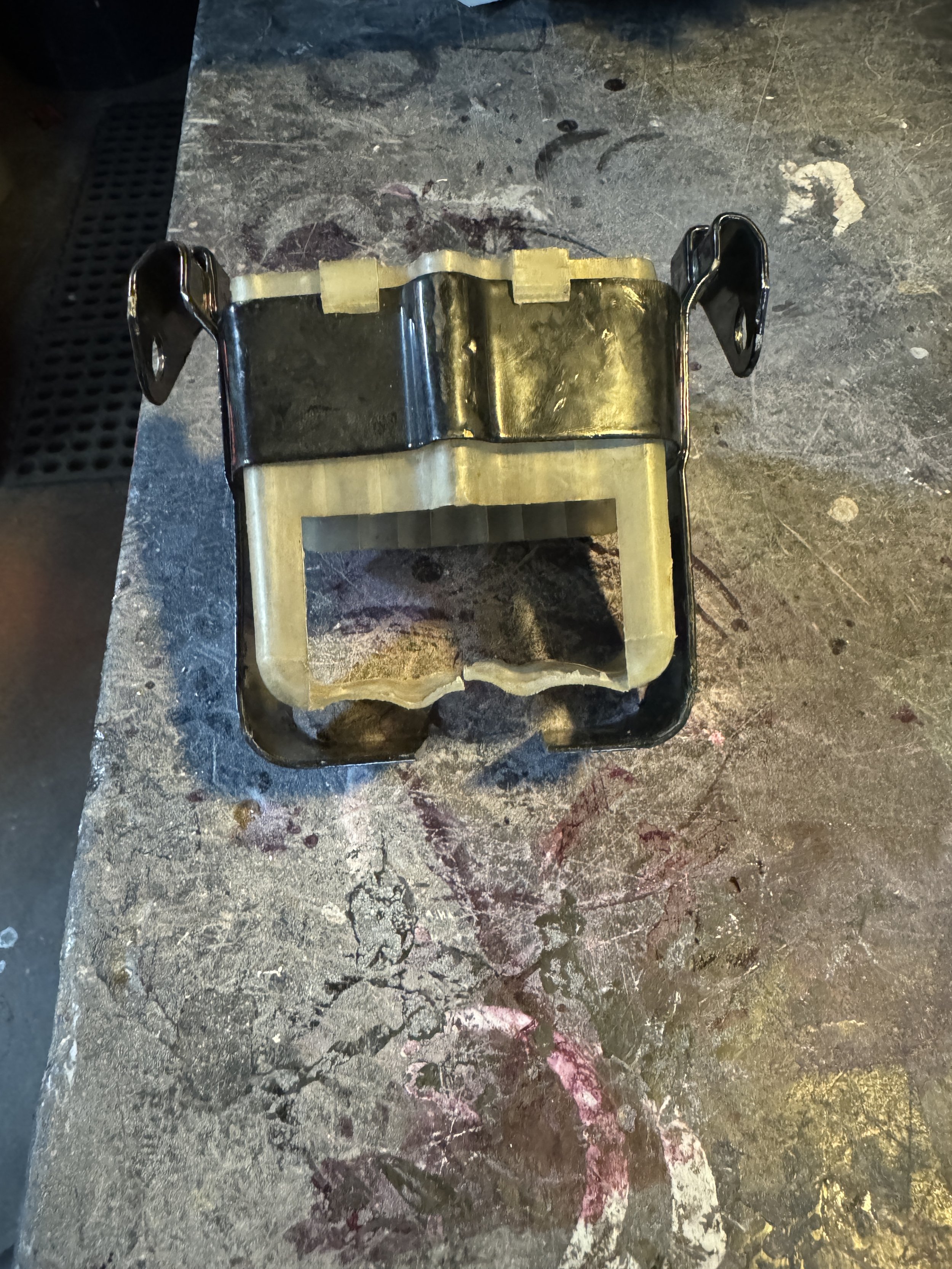

While similar to the Mark III seat, the front mounting bracket needed modification to fit with the tank and frame. The seat had been re-covered at some point, and a number of extra holes drilled into the side bars of the seat frame, to mount rivets.

The design of the original seat is unusual in that it has a thin layer of foam sewed into the seat cover, and laid over a spring frame. The original foam was falling to pieces, so a duplicate was made from high density close cell foam. In this picture, the seat assembly was getting ready to go to the upholstery shop ( Xtreme Upholstery in Denton, TX,) where the seat cover was made and sewed through the foam. The other detail that had to be worked out was the pointed tail of the seat. Since there was no original seat to model from, it was based on pictures from brochures and other bikes. A close-cell foam form was made and placed at the rear, but the fact that the rear panel on the seat is not supported by any frame at the bottom, it floats somewhat, and was difficult to support. I was very happy with the final result.

After the seat frame was modified, the holes were welded up on the side rails, and it was painted. Andy at Xtreme Upholstery did a phenomenal job on the cover, even adding the canvas underside. I added the special front mounting tabs, seat strap and badge, and the mounting side rivets to finish it off.

On display at its final destination.

A failed tank liner was stripped from the tank, and it was re-lined with POR-15

A photo prior to the front number plate and correct hand grips being placed on the bike.

The beautiful Dell Orto SS1 27mm carb and velocity stack. Everything was polite, re-plated, and missing parts replaced.

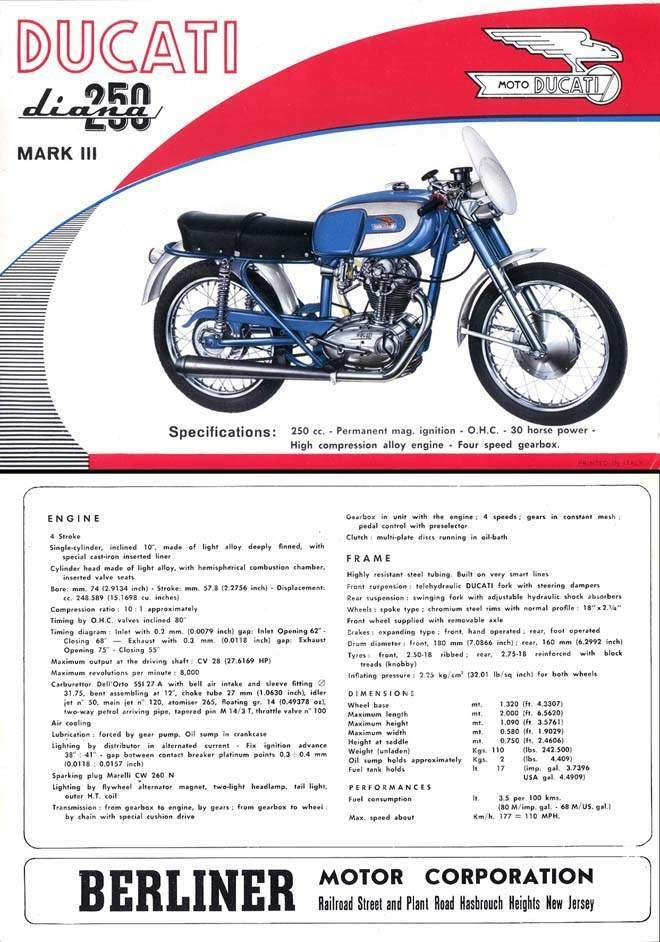

The original Berliner spec sheet. The five-speed gearbox on this bike suggests it could be a 1964 model, as the four speed was a four-speed. The serial number, however, suggest a late 1963.

The speedo is from another model, and only goes to 80MPH. The original one is hard to find, and goes up to 110MPH. Once again, the Ducati styling of this era was just classically beautiful.