A 1980 Honda Z50R frame and a 2004 Honda CRF50 engine were mated along with an extended stock swingarm, tall bars and some other goodies to make this custom, a tribute to the 1986 Honda Z50RD known as the“Christmas Special.”

A stock swingarm was lengthened 55mm using a custom jig. .250” wall DOM steel tubing was used to make the extension slugs.

Everything was stripped and blasted prior to going off for chrome.the mounting screws on the back of the muffler were leaking and subsequently brass brazed. The muffler is slightly larger than the original stock pipe. I have had some good performance from these aftermarket pipes, even though they are slightly smaller than the performance pipes sold for these bikes.

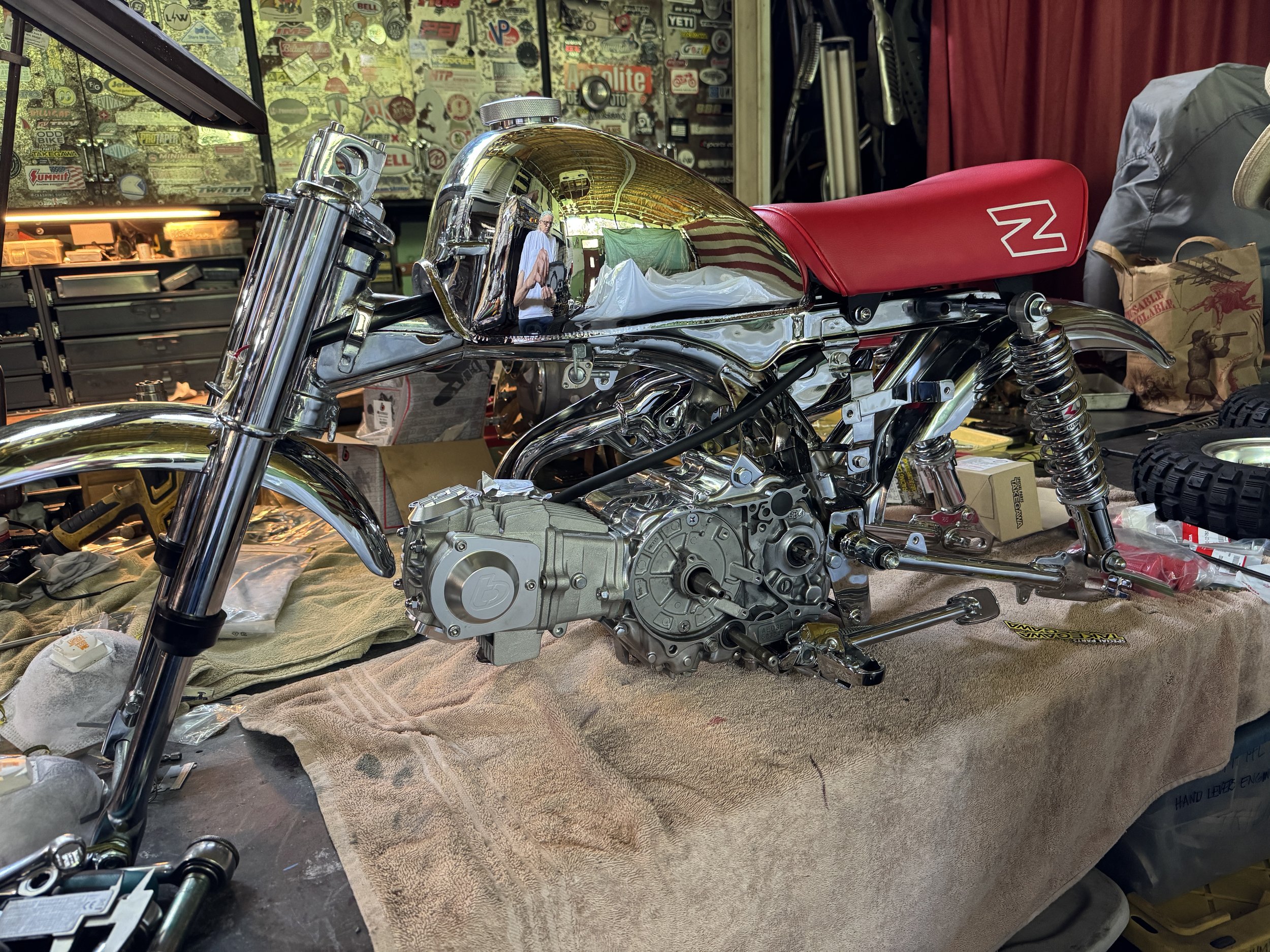

Everything back from the chrome shop, waiting to be fitted together. The footpeg mount was from a CRF50.

I bought some OEM Honda fenders a few years back, that are made to go on the Z50RD.

New steering head bearings, fork internals and seals, and swingarm bushings were used to get the frame back together. A stock ignition coil was mounted in the stock location, but will be later switched out for a Takegawa 12 Volt unit.

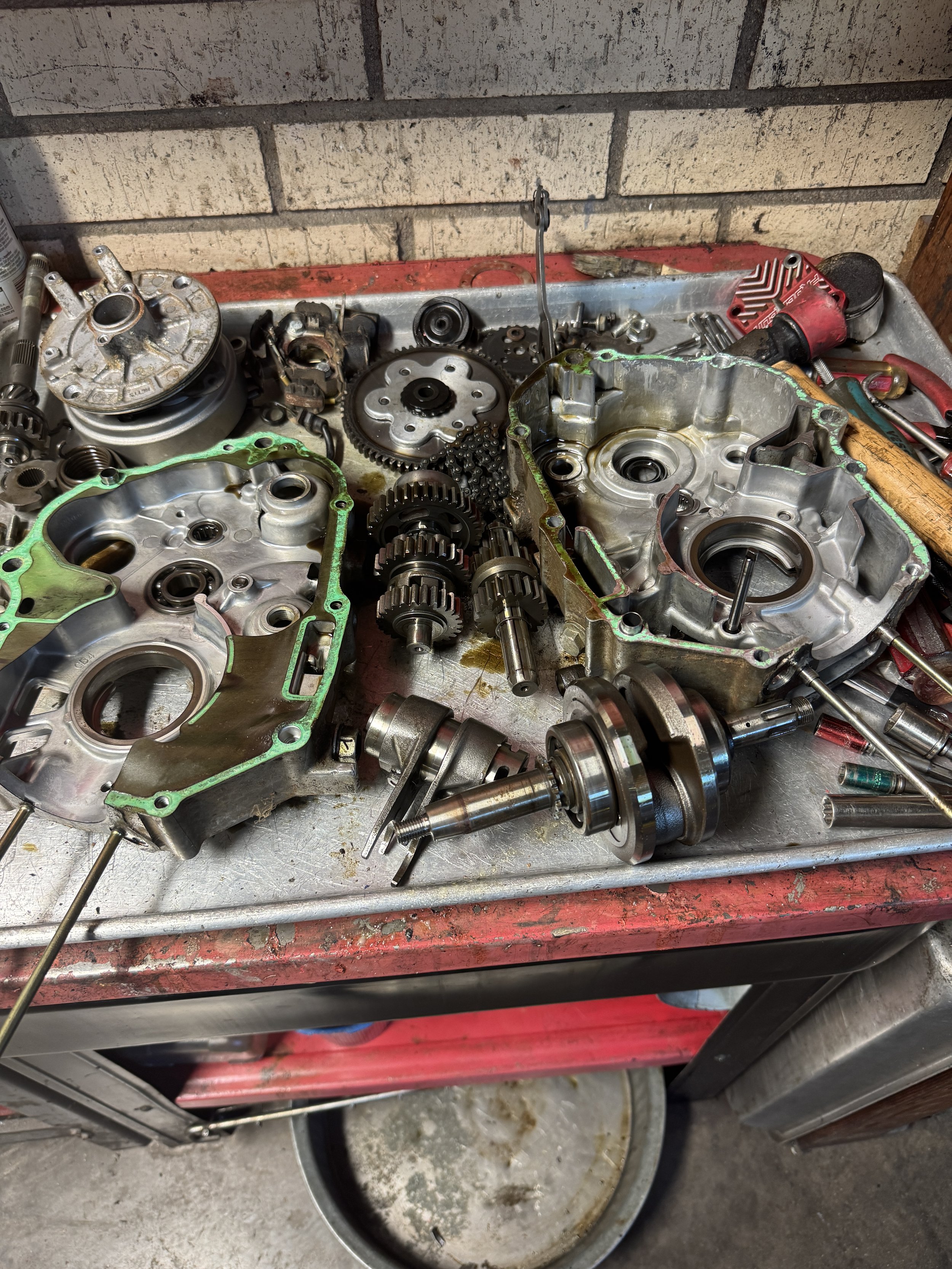

The 2004 CRF50 engine was completely dismantled. A takegawa lightened stroker crank, a heavy duty clutch, high volume oil pump, 52mm cylinder and piston, rolling rocker head, four speed tranny, and lightened flywheel will make up the base engine.

With all the chrome on this bike, the cases have to be high polished to match. A lot of aluminum parts were polished out, including the wheels, handlebars and clamps, kickstarter, gas cap, number plates, front fairing, and of course, these cases. Buffing is a nasty job, but the bling is worth it.

The engine is mounted unready for finishing. The fenders, seat, shocks, and tank being placed on the bike make it start to look like something! The rear shocks are 305mm Kitaco brand. The original shocks were 280mm, but the added length is to compensate for the swingarm extension.

New alloy rims, polished wheel hubs and brake panels from 1970-1979 Z50’s, along with some Takegawa reinforcement rings and polished stainless steel hardware make up the wheel set.

The wheels and muffler mounted and we have a roller. There will be a set of Renthal alloy bars coming soon.

The TB Parts CDI was mounted on a custom plate made to fit behind the left number plate. A custom wire harness was worked out, using a 1972-1978 style harness, and some adaptors for the CDI box, and voltage regulator. The voltage regulator is tucked under the frame, just behind the coil.

The flywheel was significantly lighten to allow the engine to spin up faster.

A 90 Watt Ricky Stator was used to keep the light good and bright. This one was made for the CRF50, and has three wires coming off the pigtail.

Number plates made from .050 aluminum. They were made using a powered bead roller. High polishing will be next. It took a couple tries to dial in the size, but they are now exact matches.

A chain guard being made from steel. Because of the extended swingarm, a stock guard would not fit. Though the original was black plastic, this one will be chrome plated. The indentations on the side of the guard were made with a bead roller. Some of the parts of the indentations were worked with a ball end punch, and a coining punch on the backside.

A tail light was built using an existing lens. The final one will be red instead of amber (just using it for mock-up to keep the red one scratch free.) The shell and reflector are made of steel and will be chrome plated. There is an existing hole on each side of the frame that will allow a single long bolt to pass through, and secure the unit.

Coming up: The next post will cover more details of the build including a bikini front fairing, and hopefully the bike being taken off the bench.