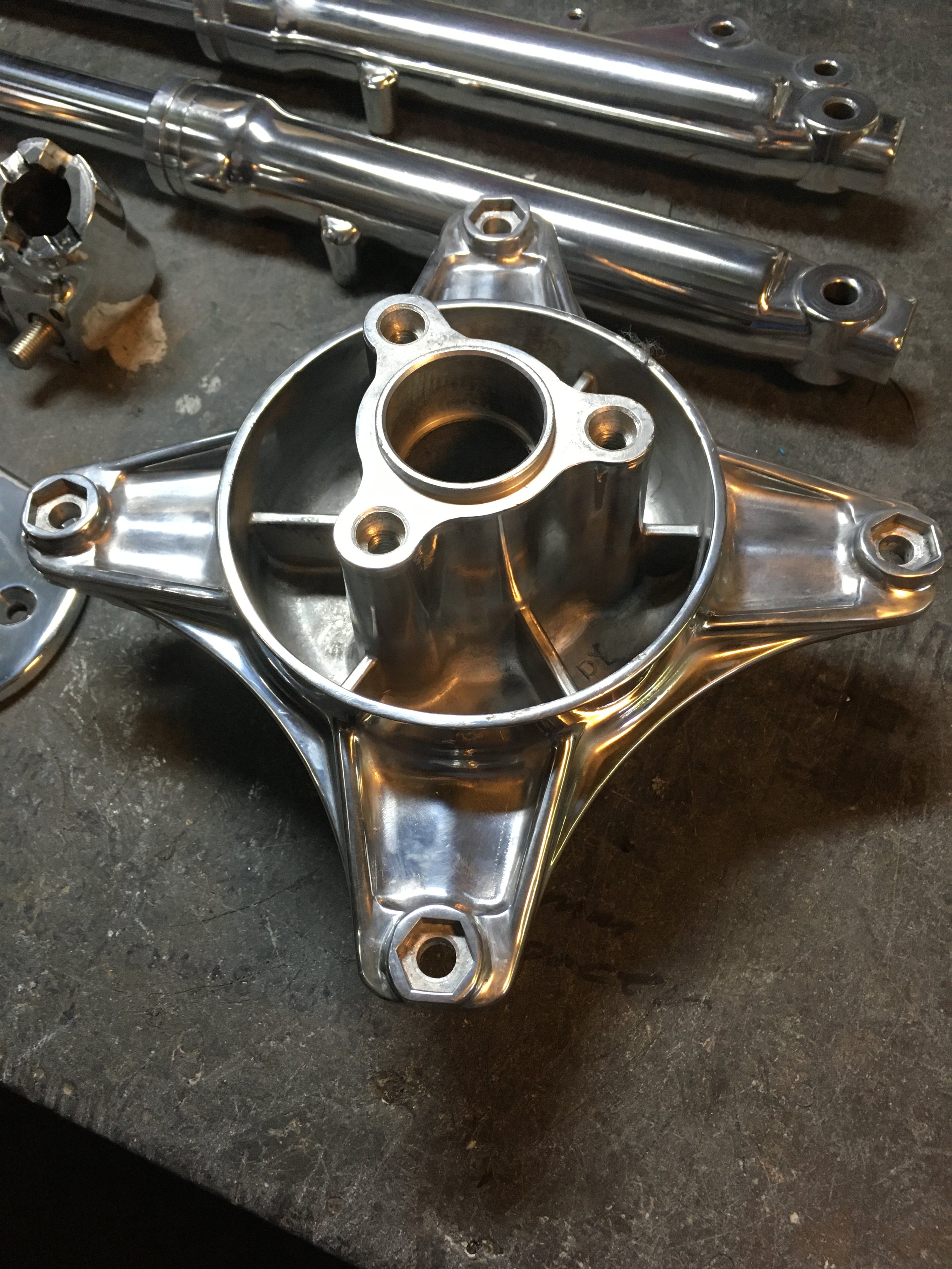

With the tins out for bodywork, the focus has been on getting all the aluminum parts polished out. When it comes to final finishes, there is always a balance that needs to be struck between the powder coat, chrome, paint, and polish. Keeping the chrome and polish on this build down to a few key components, going for tight and classy, and letting the lines of the bike bring some of the bling. In addition to these parts, there are some wheel rims that will be high polished.

All the shiny parts…when you are staring at the same set of parts prior to finishing, there is a slight feeling of dread, as the process is a lot of messy work. Nice to be on this side of it.

Stripping paint off is the first of many steps. After this, bearings will be removed, and the sanding and refinement will be done. There are small stubs around the nut recess on the tips of each spoke, that will be removed. They are a remnant of the casting process, and serve no purpose as far as I can tell. The finished wheel looks better without them.

With the sprue stubs removed, they look a lot cleaner.

The recesses took a lot of effort. Sometimes they look okay until you start buffing, and realize there is an oxide layer that needs removal. A combination of wet sanding, rotary abrasive wheels, and polishing wheels of all different sizes were used to get them done.

The rear hub used during mock-up is a one-piece type, and did not match the front wheel very well, so an original CT70 hub was sourced in decent shape. The other big plus with the original hub is that it has a steel tube cast into the hub for the rear sprocket retainer ring to fit into, opposed to the one on the one-piece wheel, which is machined out of the aluminum wheel casting. While not something you might think would be subject to much force, side to side, the rubber cush drive the sprocket tabs fit in will push outward on hard acceleration and braking. If the thin lip of cast aluminum holding the retainer C-clip in fails, the sprocket can come loose from the hub! I have seen one case of this exact wheel failing in this manner on an online forum. Since this one matches the front style, it gets the nod.

The after on the wheel hub. The parts all were cleaned in a hot ultrasonic tank after polishing. The steel brake lining was also freshened up on the lathe.

The fork leg on the left has just started to undergo the first polishing steps. The bungs on the upper part of the forks for the front fender mount will be ground down a little, to make them more rounded.

After machine polishing, everything gets a hand polish with some Mothers brand polish.

My buddy “Mobtown” Mikey Smith is smoothing out the tins and laying primer down. There is some thought being put into making some molds off these parts for fiberglass reproductions. Mike and I have worked together in the past, doing some silicone mold making on a “Dragula” clone coffin body, being made for a Munster’s star.

A House of Kolor paint color called “Wild Cherry” that matches the bike owner’s vintage Ford Bronco, was chosen for the finish. The bike will also have the white lower section, similar to the Honda CT117.

Getting excited to see these tins getting done.

Thanks, Mike!

Also sorting hardware to take to the zinc platers, and the parts for the chrome platers. All the hardware will be stripped and wire-wheeled before plating. There is a fair amount of stainless hardware that came with the bike that will get polished and re-used.