The complete restoration of the 1967 Triumph T20M Mountain Cub was finished recently. A year ago, a friend and I were at Big D Cycle. I thought I was getting ready to buy this bike as the basket case it was, when my friend asked my intentions with it. My reply was that I would just put it on a shelf, thinking someone might want it someday. My buddy said he was that someone, and asked if I was interested in rebuilding it for him. Having recently completed another Mountain Cub, I thought it would be a similar experience, but that did not prove to be the case. The wreckage and rust in the engine shown in the previous post, along with some hard to find parts, slowed down the process. A few curveballs, like ill-fitting new parts, a bent sub frame and swinger, and an incorrect points plate added to the frustration. In the end, she is a running, riding example of the stock Mountain Cub.

A lot of small details go into a restoration. New badges had to have the tank colors painted into them.

To paint the tank badge recesses, they had to be masked a couple times: once to scuff them up, and a second time for paint.

The finished Badges, re-plated cap, and kneepads have the tank looking done. The paint was done by Jason Small, of Dallas, Texas.

The original side cover and tail-light mount pieces were in decent shape and were polished up.

The primary cover was said to be NOS when purchased online, but it had a dent in need of some persuasion. The dent was carefully tapped out, followed by a good polishing.

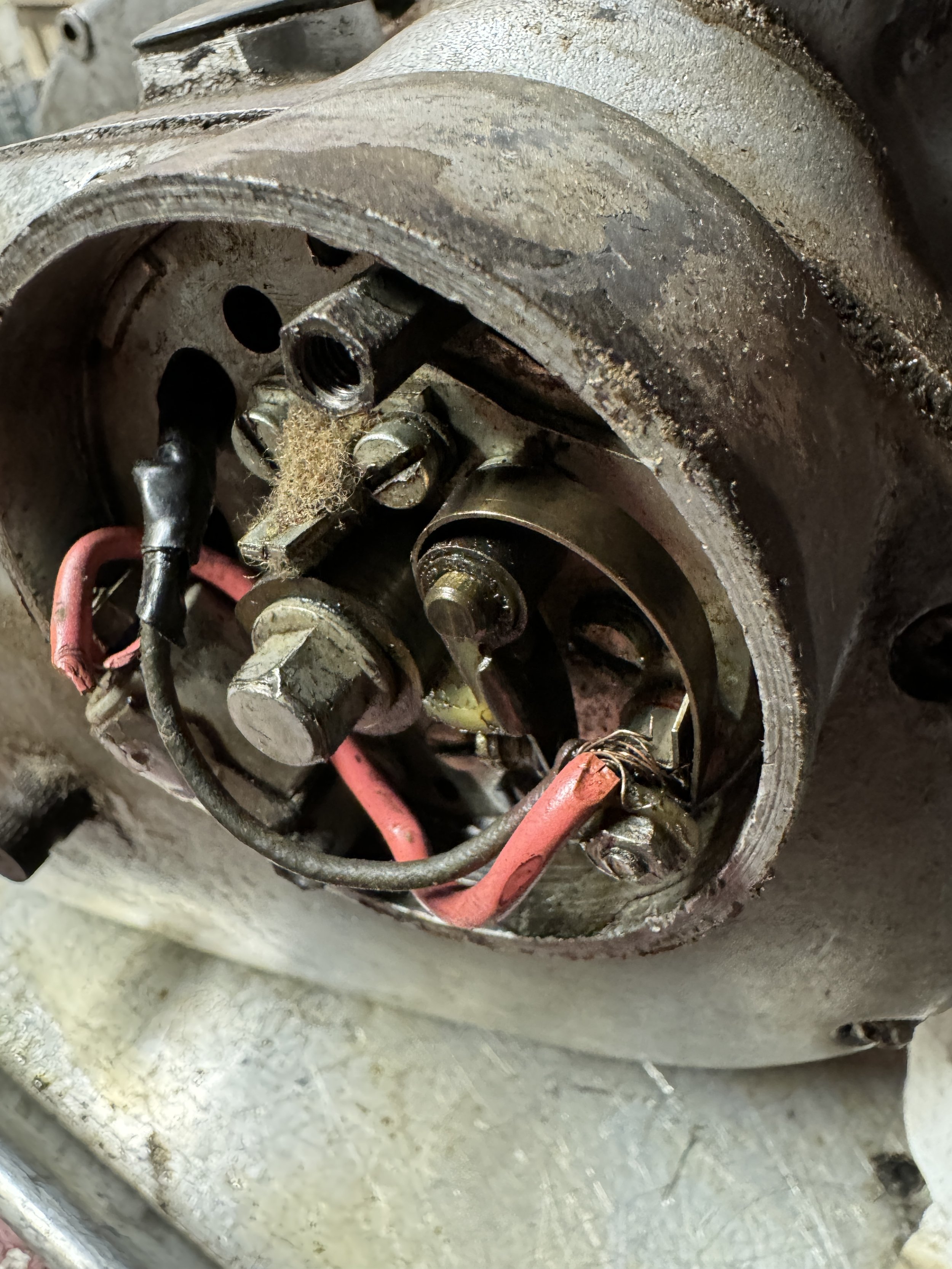

The aforementioned points plate. In retrospect, I should have known it was bogus, given the skill level of the last person to work on this. In the end, a used plate was sourced from Klemph’s British Parts, along with the correct set of points.

The new Lucas stator and fresh cadmium plated hardware have the primary cover looking done, but the factory sheathing on the pigtail, beside being imprinted with white lettering, is oversized, and does not fit through the exit hole. A smaller unmarked sheathing was found, and the original wires were fished through it. Thinking the larger sheathing is not an issue on other larger bikes.The cub has Triumph ET ignition, also found on larger bikes. The new sheathing can be seen in the pictures of the finished bike.

Stainless steel rims and spokes were sourced from Devon Rims in the UK.

Everything starting to go together. The forks were completely rebuilt, with the top fork caps once again requiring three different sets purchased till the “right” ones were found. I say” right” ones, because while one threaded easily, the other one took three hours to fit into the tops. The threads were not quite right, probably as a result of the chrome plating process, and had to be cleaned before a smooth fit was achieved.

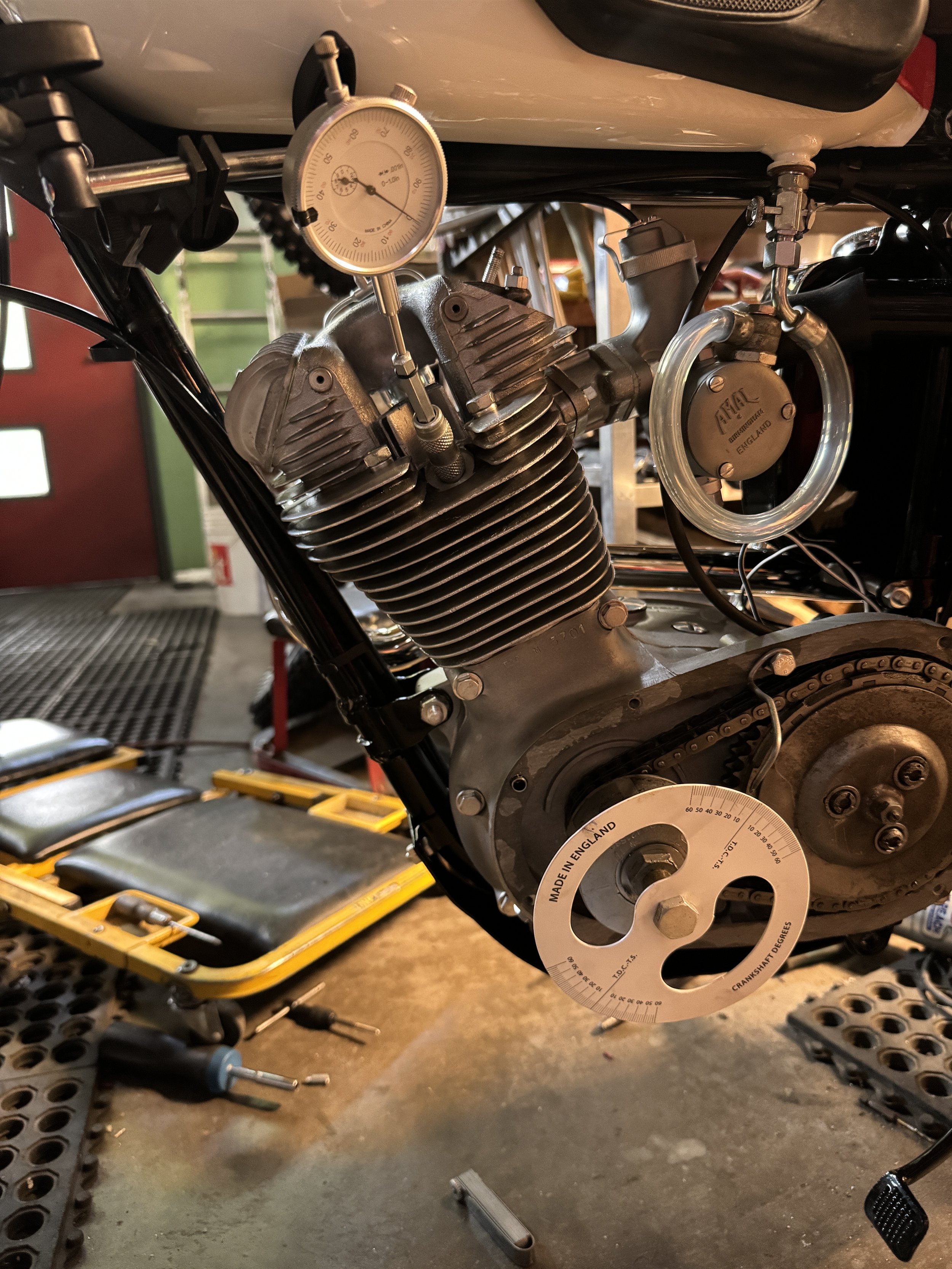

With the cam and timing gear in place, ithe engine is just waiting on the push-rod tube, and the head can be torqued down, and the side covers put on.

Getting the timing worked out.

One of the curveballs in the build was misalignment of the rear frame. In this picture, the difference is being worked out using a spacer on the left side. the subframe was taken off and straightened a little bit, allowing the fender to line up.

The finished bike. The oil stains on the concrete were from the first start-up. Yet another curveball, a pinhole revealed itself in the steel oil pipe coming out of the oil pump.

The hole in the oil line was small, but with the oil pump’s pressure, it was a squirt gun. Prior to re-plating, there was no significant rust on the outside of the pipes, suggesting it rusted from the inside out. Kind of unusual, but given the rust in the engine, it now makes sense.

Three miles on the odometer, the bike has been started, ridden, and is going through several heat cycles.

Big change from the before pictures seen in the last post.

Ready for fall.

Have always appreciated the beauty of these engines designed by Ed Turner.

The entire headlight assembly was missing, and was built from an aftermarket shell, and a lot of NOS Lucas Electric parts.

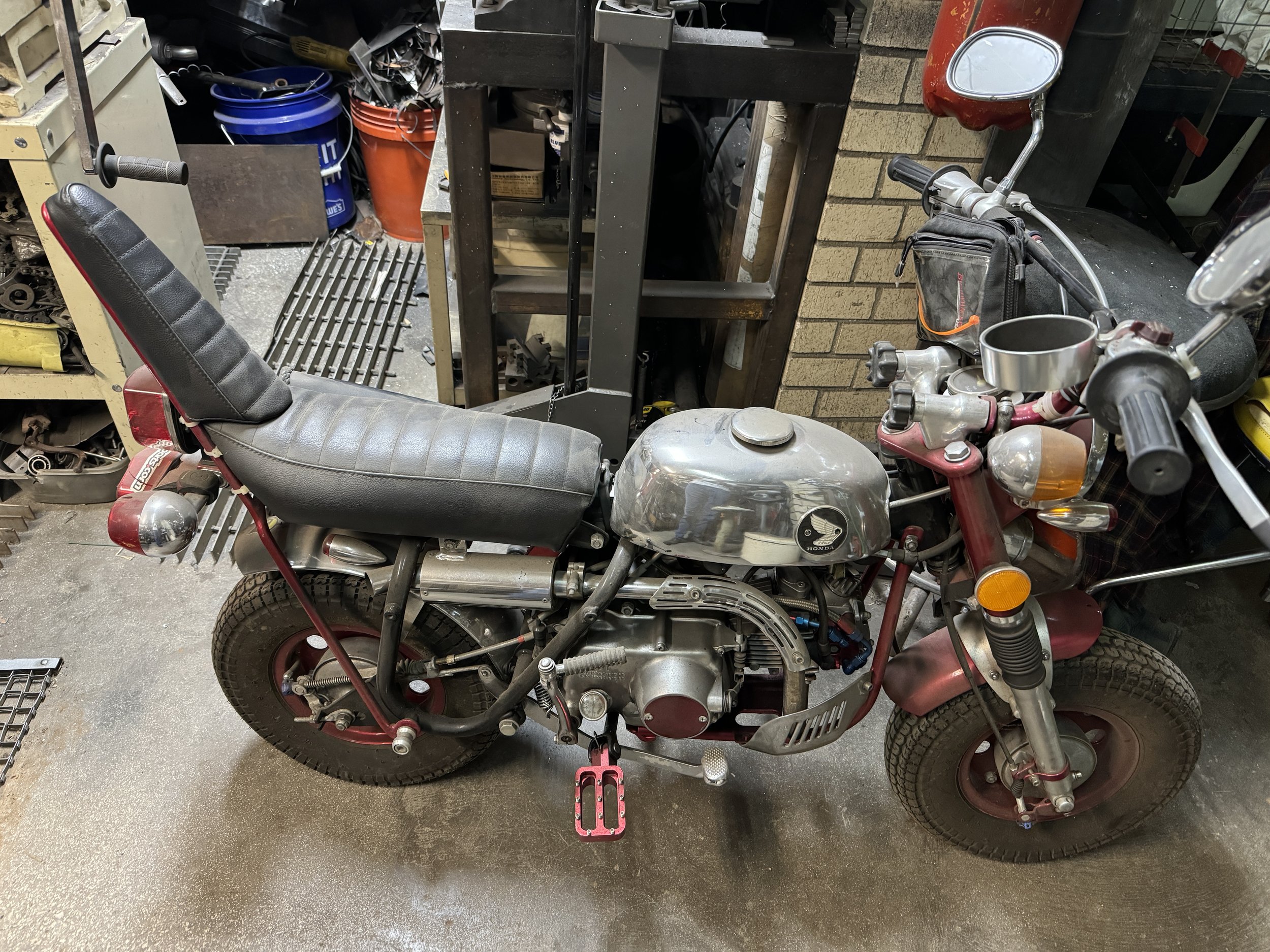

The bike being put together to make it a roller at Big D Cycles in Dallas, Tx. prior to the rebuild. The journey began at Big D, and ended….

…at Big D Cycles! Here in their parking lot, after my buddy’s first ride.