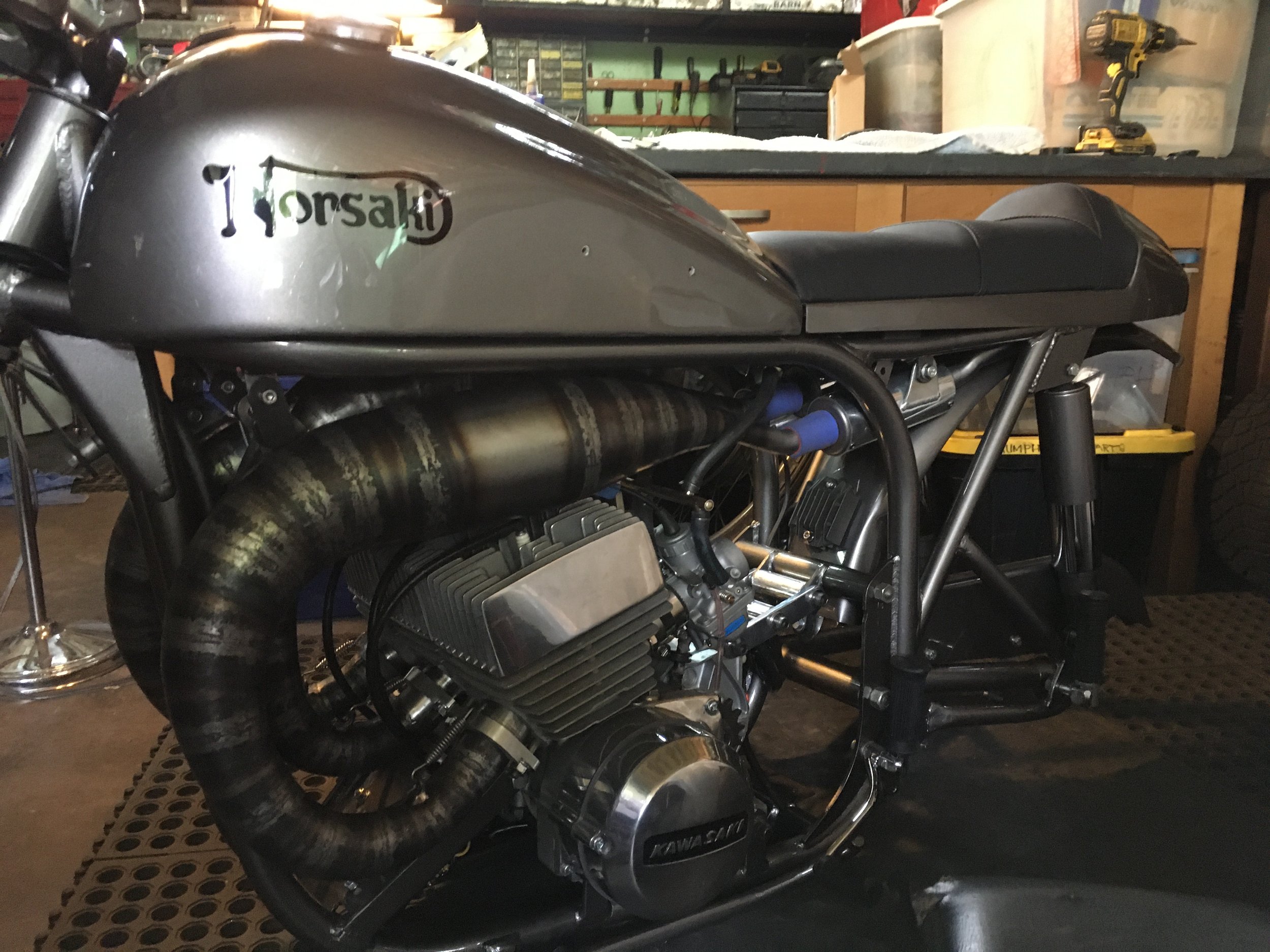

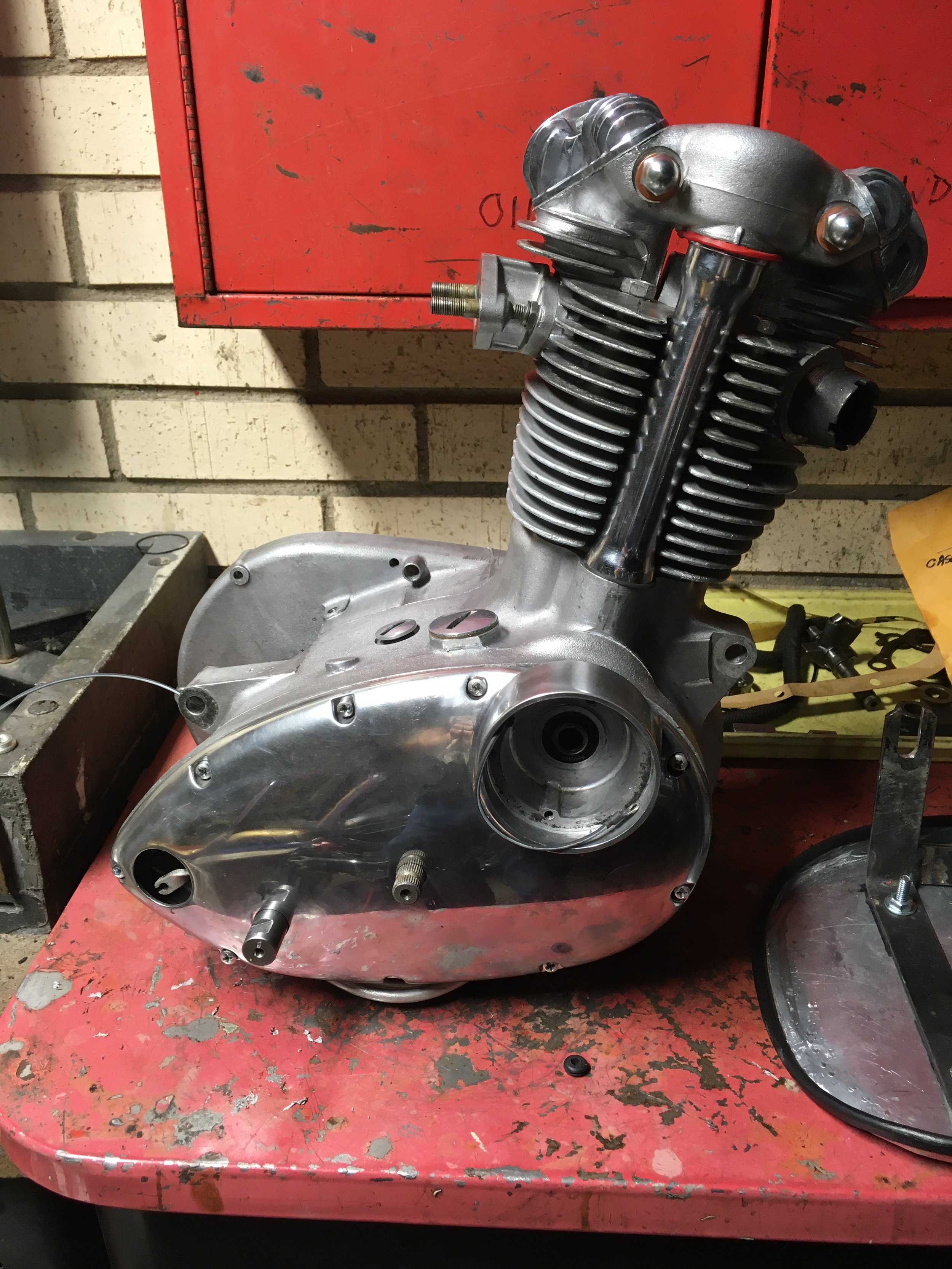

Time to begin another custom small Honda build. Based somewhat on the CT117, built in 2010, there will be similarities, such as the long, low stance, the rear-hinged seat with the gas cap poking through, and low handle bars. With a good bit of the fabrication already done, the plan is to add a few more things like footpegs, engine cradle, exhaust, and possibly a front fairing, before moving on to finishes.

One of the first jobs was getting the stance right. The front fork tubes and springs were shortened about 45mm to get a similar height to the CT117. The handlebars were made from the stock bars. With the bars in place, a round headlight just looked wrong. It was either too high or too far forward to fit in. I had a rectangular signal light from a big rig, and it made the front come together. Don’t know if the amber lens is going to stay, but it looks pretty cool. The headlight is mounted on a custom tubular steel bracket that utilizes existing mounting holes. Without headlight ears the fork tubes stay clean.

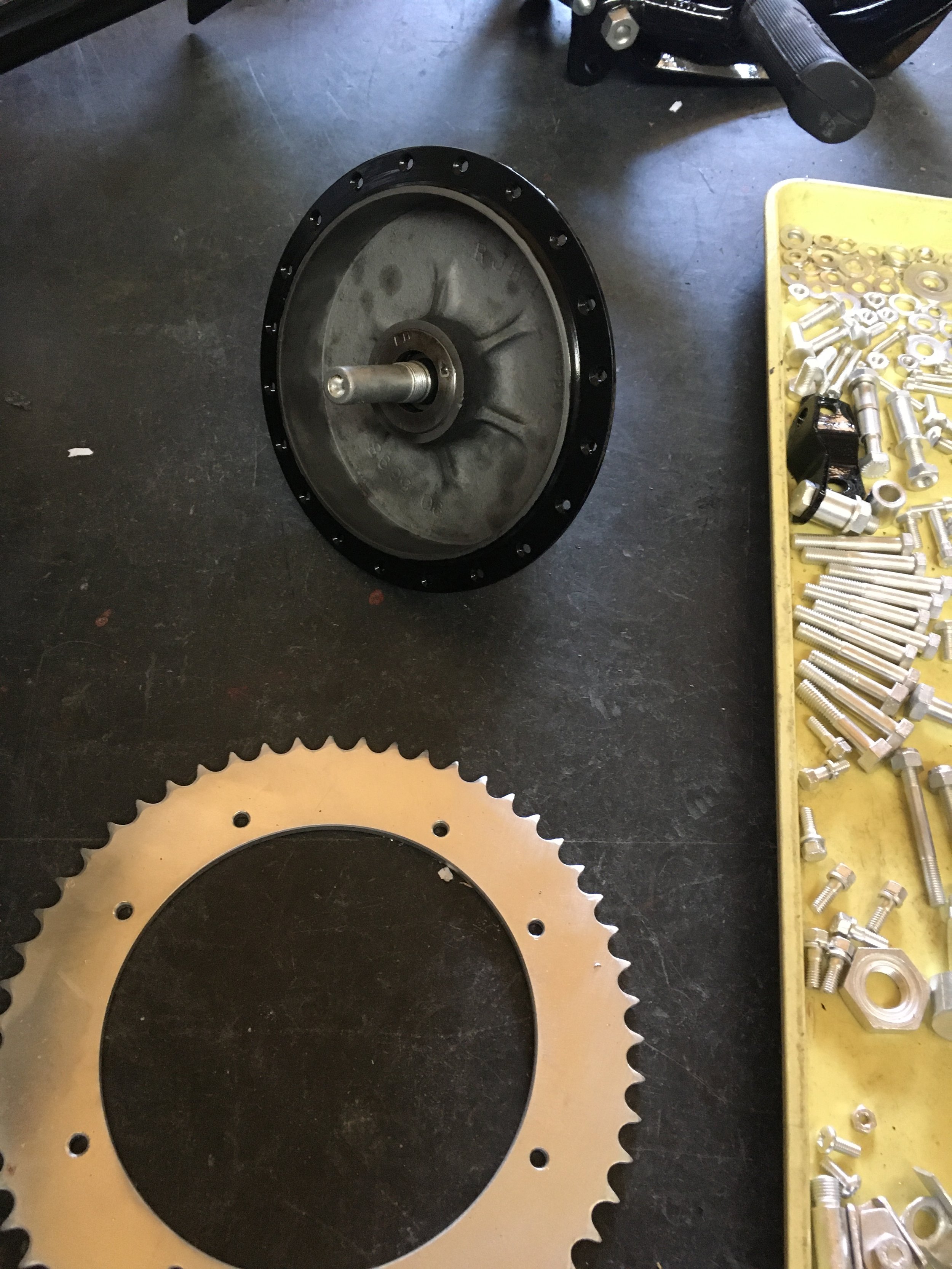

The swingarm is from a Honda XR80, and has been lengthened to 16” There are custom covers on the sides of the swingarm to echo the frame body lines.

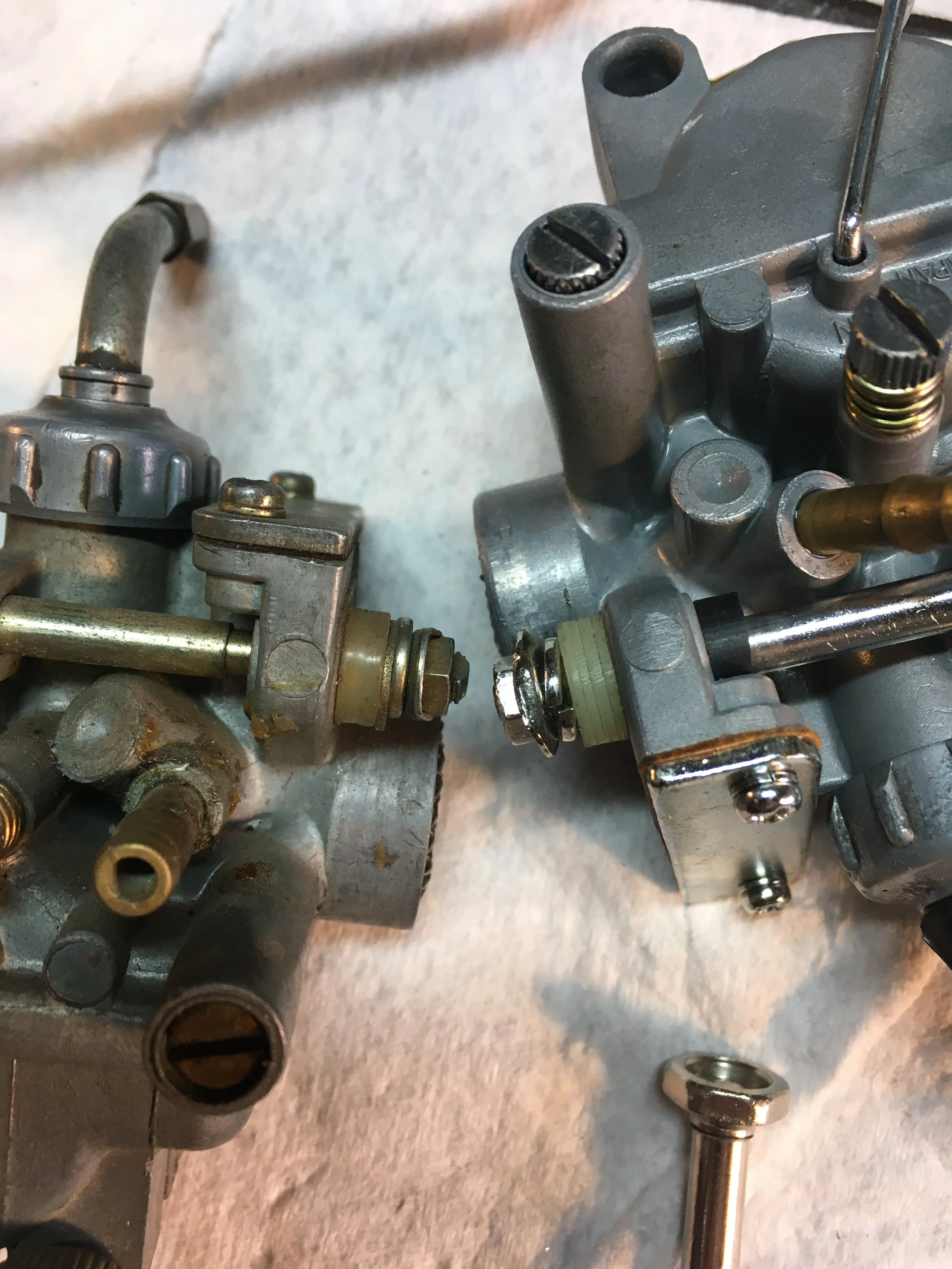

A hydraulic front disc brake came on the bike, but shorter, more compact levers and master cylinder were needed to fit the build. The master cylinder is just resting loosely until things like speedo placement and a fairing are figured out.

The rear fender base fits in the recess of the swingarm nicely. The swingarm used for this bike is significantly different from the stock one, in that it mounts to the outside of the frame, opposed to the inside recess, as the stock CT70 does. This is how the Honda ST90 is set up, basically. Some bracing and an inner spacer will need to be added once the bike is broken down.

The chain guard is a favorite of mine. The magneto cover will be opened up to reveal the counter sprocket. The original CT70/Dax frame is a beautiful piece of art. The design blends rounded organic curves with chiseled geometric lines, that I feel are often overlooked. When the original swingarm was replaced with the longer tubular one, the beauty of the original was apparent. This led to the side covers on the swingarm, that are meant to add some of that angular, curving lines back to the design. The chain guard and seat were designed with the same thought in mind. The lines of the rear fender echo the rear frame curves.

The seat assembly is a big part of the build, and has taken a good bit of time to get to this point. The design took a little time to form, but once decided, the seat pan was made first, with a seat frame and hinge then made to fit the pan, and finally the tail light assembly and aluminum sconce around the fuel tank cap.

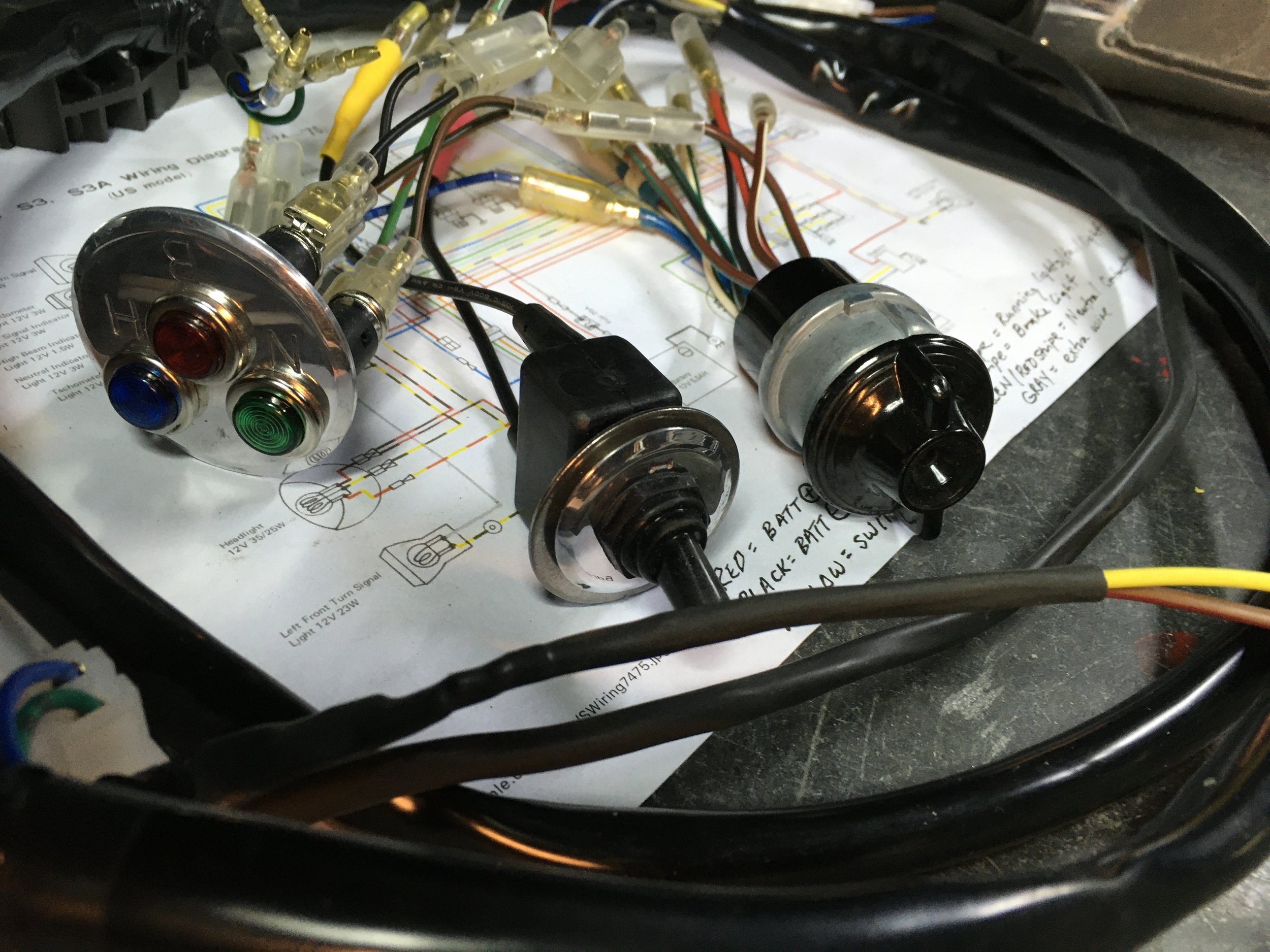

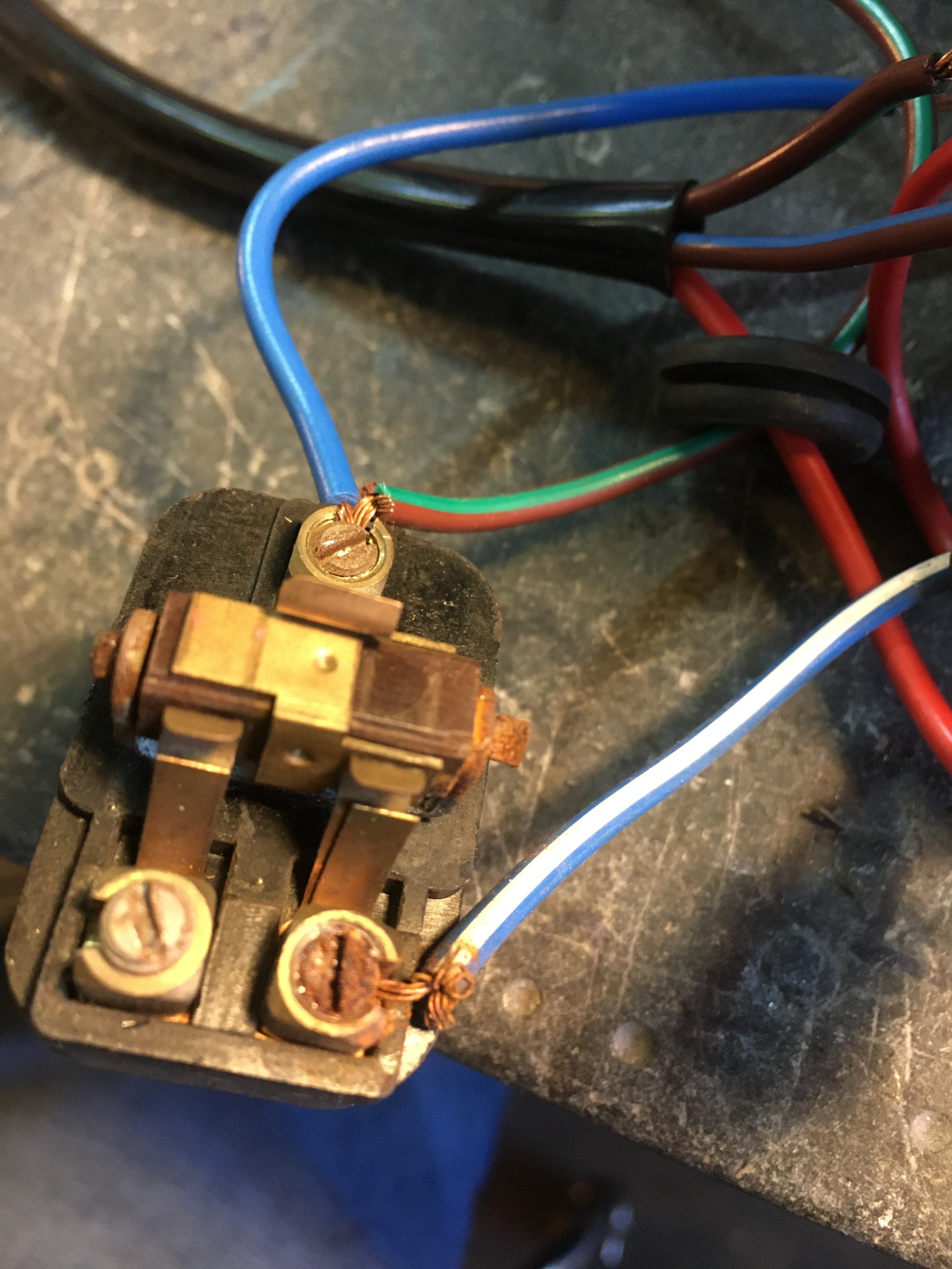

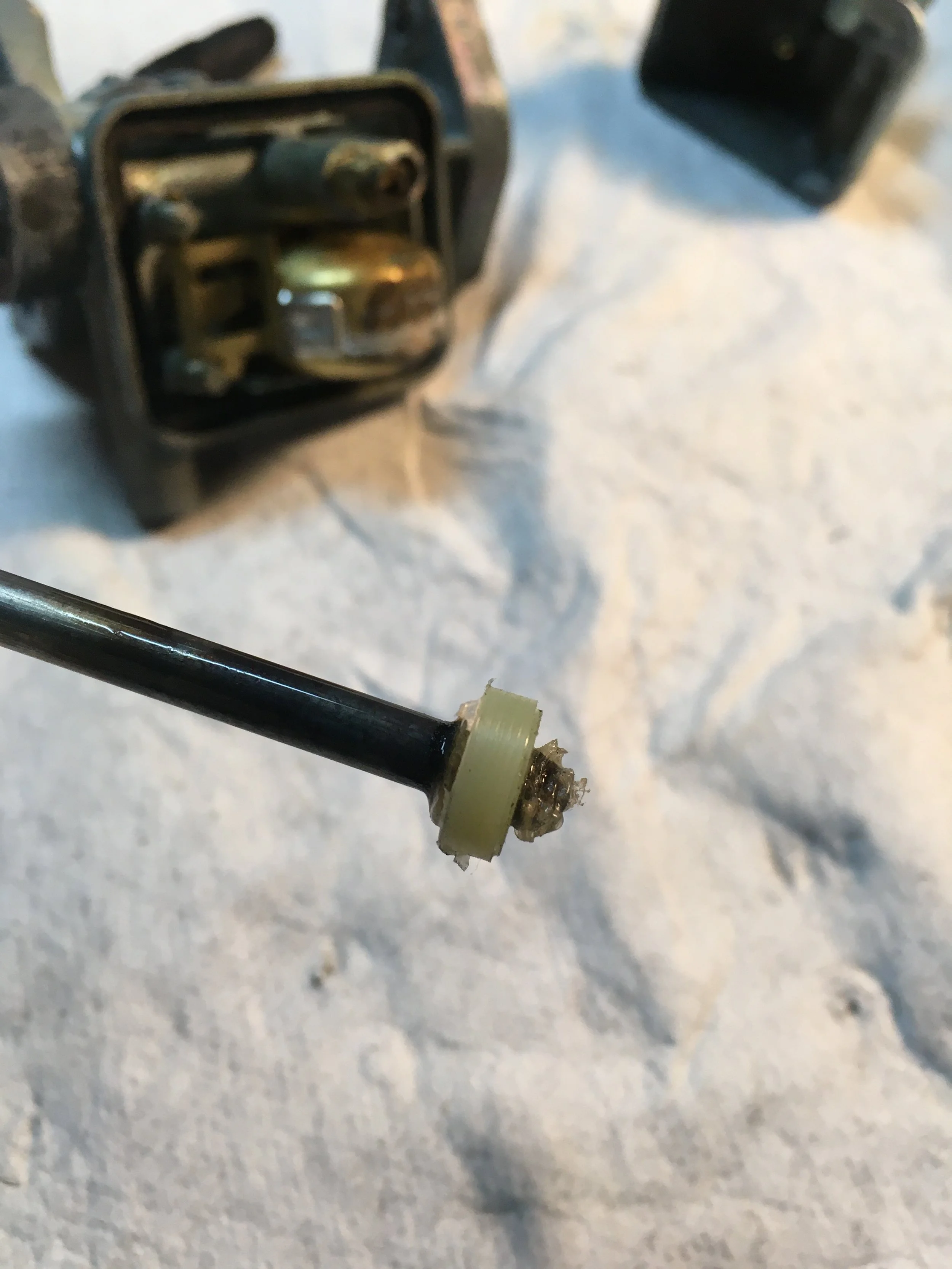

The thumbscrews for the seat are ready for brazing here. They are machined to press fit together with a thick head washer underneath used as the base.

After heating, the parts were brass brazed.

The thumbscrews in place. After chrome plating, they will go nicely with the gas cap.

More rectangles cut into the seat frame and hinge, mostly to lighten things up. Some Honda rubber bumpers fit in the smaller holes toward the rear of the seat frame, that rest on the stock frame tabs like the original seat.

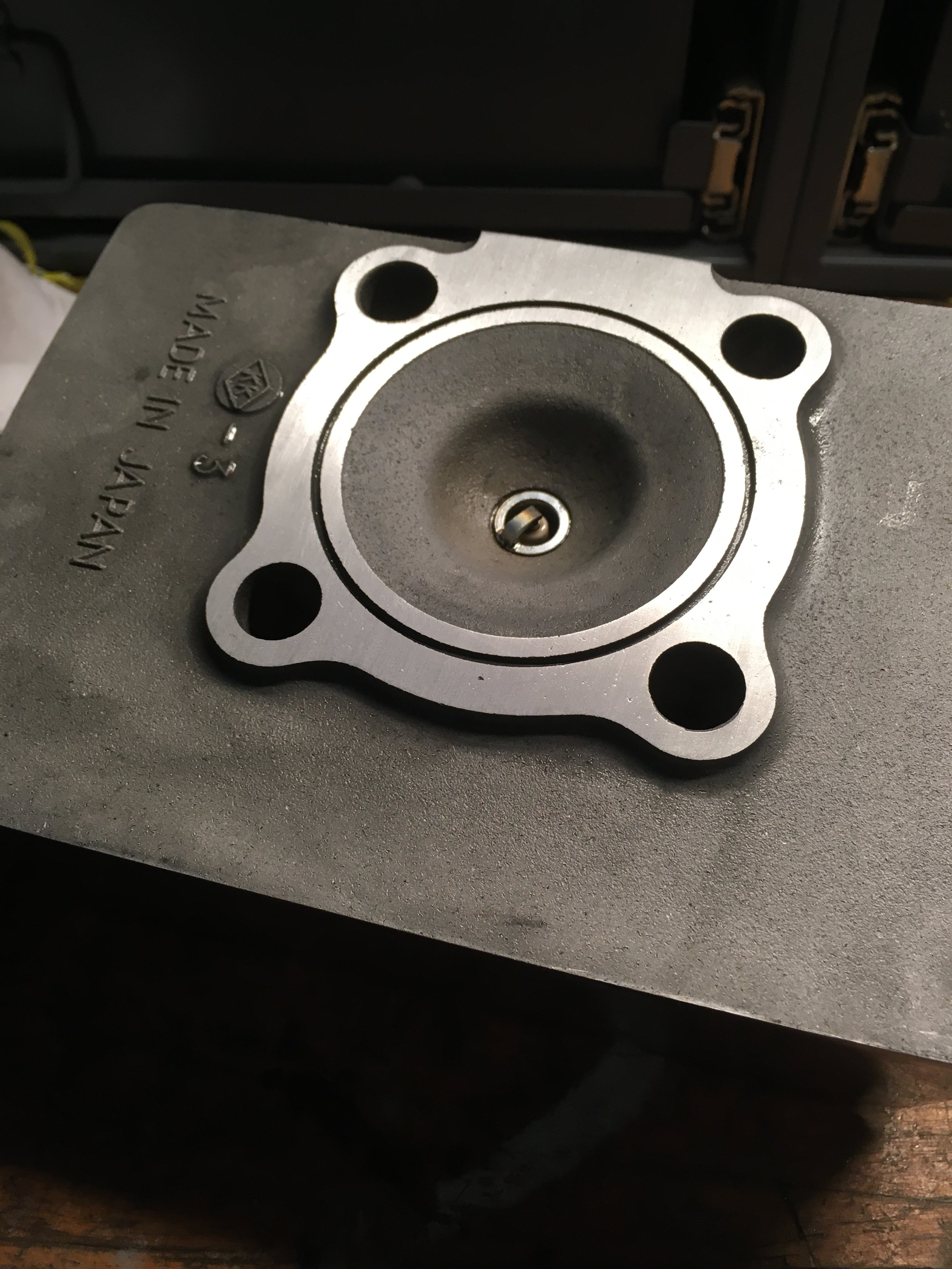

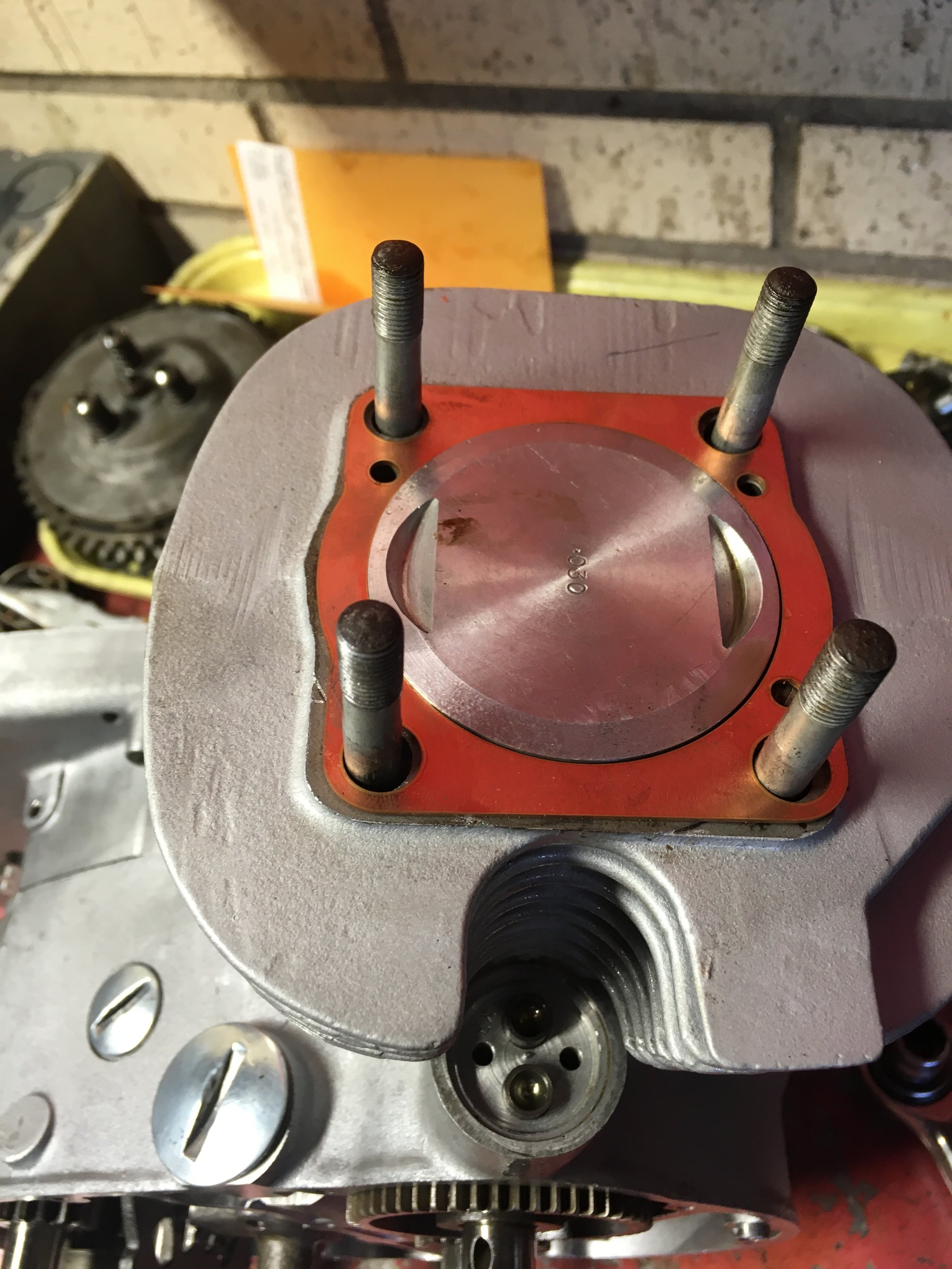

In order to make a uniform recess on the rear seat panel for the tail light, a hammer-form was made.

After the panel was worked on the hammer, form, a second rectangle was added to the backside to hold the brake light lens. This is the snap-on reflector and bulb assembly, and the access hole to reach it once the panel is welded in.

After some clean up, the rear panel is ready to weld to the seat pan.

Simple and clean, and goes perfectly with the front light.

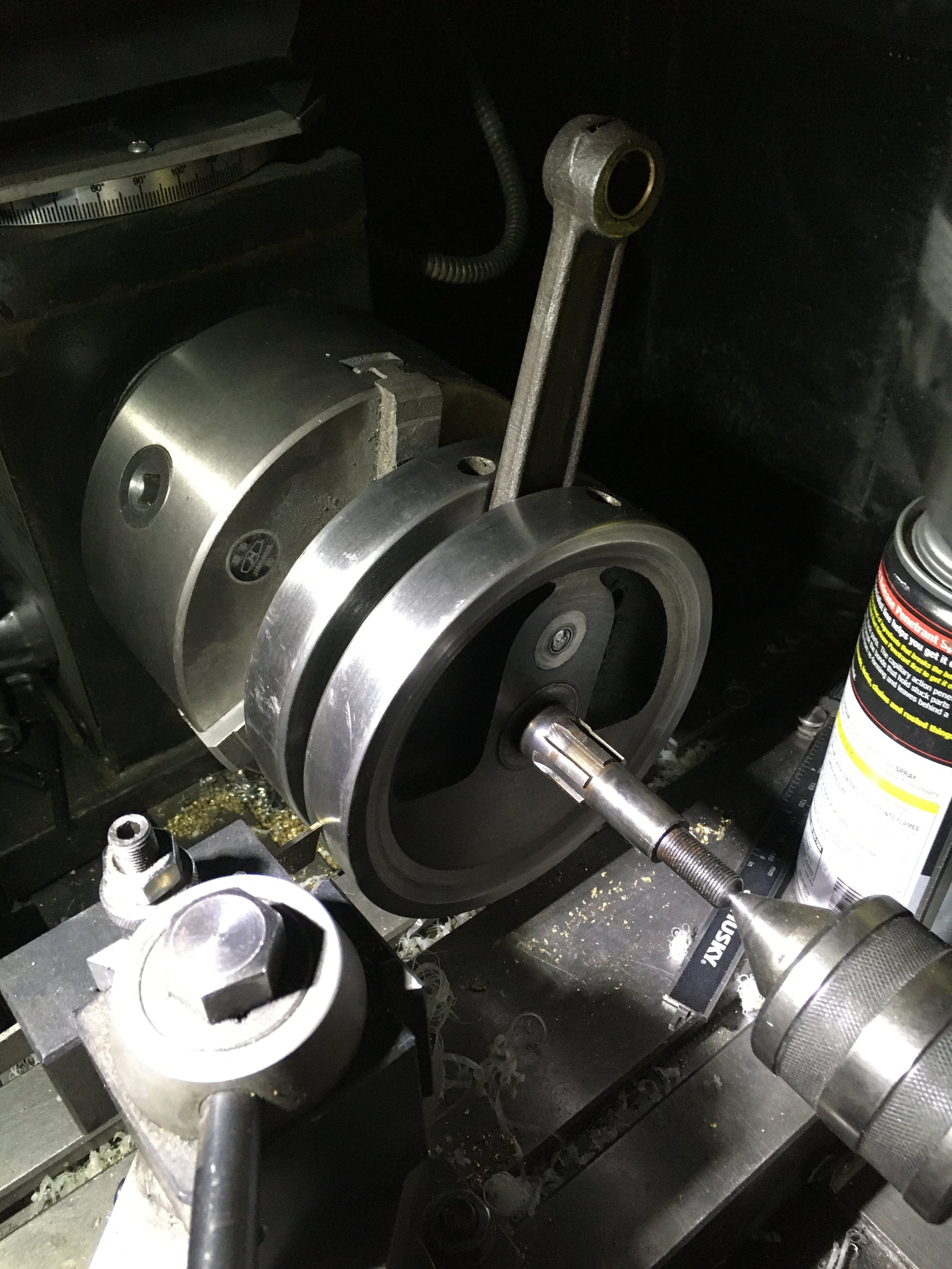

There are inner and outer springs as well as the fork tubes that had to be cut down. The fork tubes had to be re-threaded after they were cut down, for the top screws.

The shock lowering brackets were another part taken from the CT117. They allow the long swingarm to be used without really long shocks to keep the ride height right.

The front forks will have to get some machining on the mounting screw bosses to mount the custom front fender and fork brace. The brace is hidden beneath the fender.

The front fork brace can be seen at the top right. This picture represents the one hundred plus degree days we are experiencing in Texas, and my struggle to keep the sweat off them so they won’t rust.