Starting to assemble the 1967 Triumph Mountain Cub. Every nut, bolt, and body part has been taken down and addressed aside from the original tank paint. Still waiting on parts to get the engine back together. The wheels are another area of concern. The front fender needs to be worked out. Small touches like a light weight tail light assembly and solo seat are also planned.

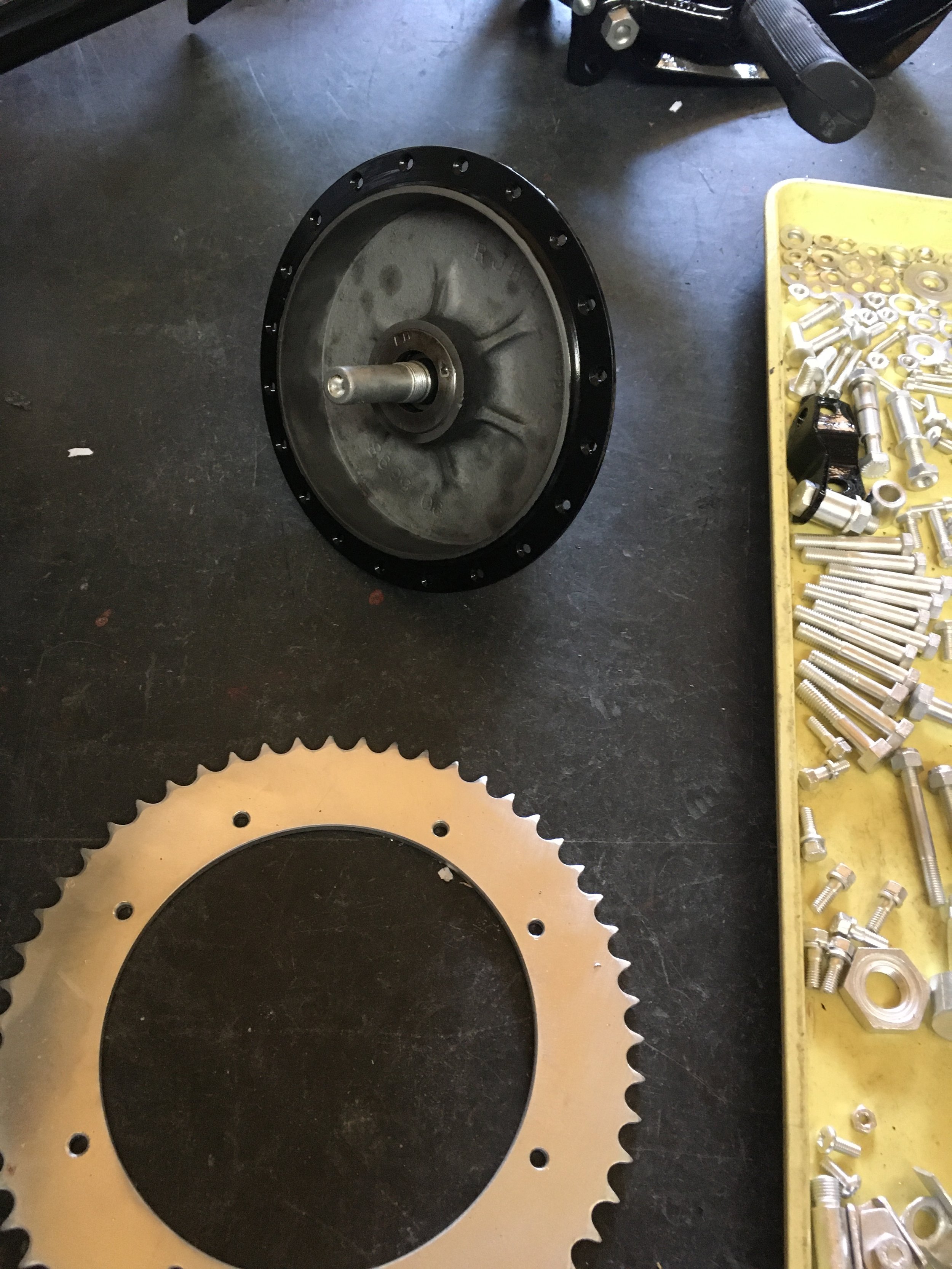

Getting a little farther into the assembly. The rear wheel has been a headache. The Triumph Tiger Cub is a little harder to figure some of the part numbers if you do not know the actual model you are dealing with. The Mountain Cub variety is even harder to figure out because there is not a parts catalogue specific to it (at least that I can find.) Perhaps this is because the model was produced at the very end of the Tiger Cub run, or because it was a US only model, but whatever the reason, there is some guessing that I have had to do. The bike came with a WM-3 wide wheel. After checking the latest Sports-model parts catalogue from 1965, there were two different wheel possibilities, but only one for a WM-3 width. After purchasing that specific wheel rim and lacing it multiple times, there was no way to get the spokes to fit correctly. After more research and hunting, the correct rim turned out to be the WM-2 width one. It appears the rims of both wheels were switched out at some point, and the WM-3 rim was substituted. Fortunately the wider rim can be used elsewhere, as it fits 63-70 650’s and other models. The front rim spoke nipples were way too small for the rim holes, and were swimming around in them. A new set of front and back stainless rims and spokes is on its way.

After the body work, the tank looks nice and smooth. It was primed and painted with rattle can enamel.

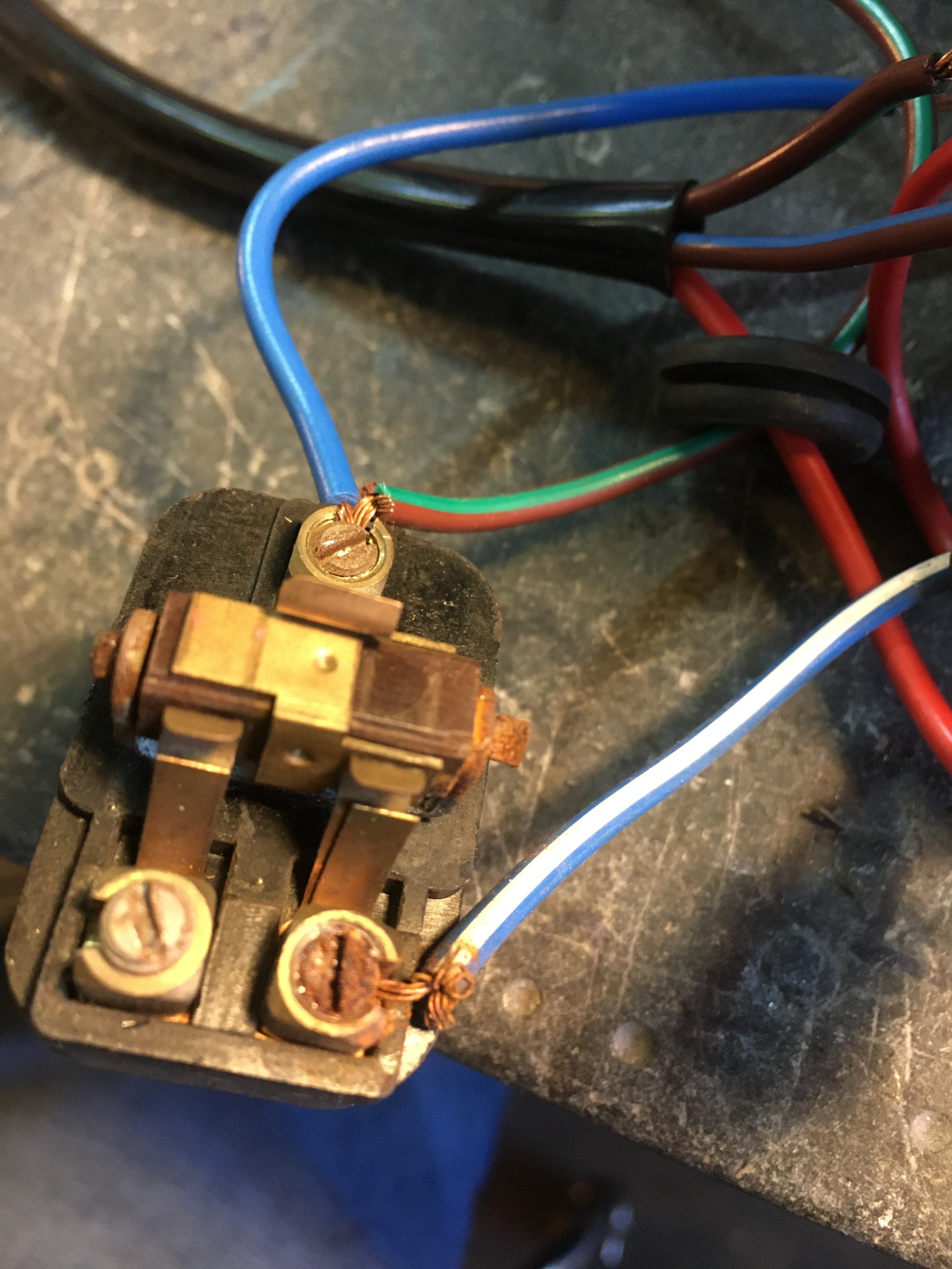

Nothing like fresh finishes on everything. Still not decided on the tank paint, but that decision can wait till the front fender is made, as it will probably get some paint as well. All the switches were cleaned and greased, connections were freshened up, and the wiring harness was restored. Some new sheathing and some missing connectors were replaced. The handlebar switches were also restored, and the wiring hidden inside the bars. A mounting bracket for the horn is all but invisible hidden behind the headlight. It uses the handlebar mount bolts to secure it. Since the original bracket was absent, and pictures showing it look like it was made for a different horn than the one with the bike, I just made something that worked in the space allowed. The wiring harness was modified to have a single sheath of five wires passing from under the tank to the headlight. Usually, there are connectors from the horn and kill switch that pass separately along side the main wiring harness. Instead, the ignition wire was added to the harness bundle, and routed to the headlight, where the horn and kill switch connections were made.

This tray was packed with hardware. As it dwindles in size, it makes me happier and happier.

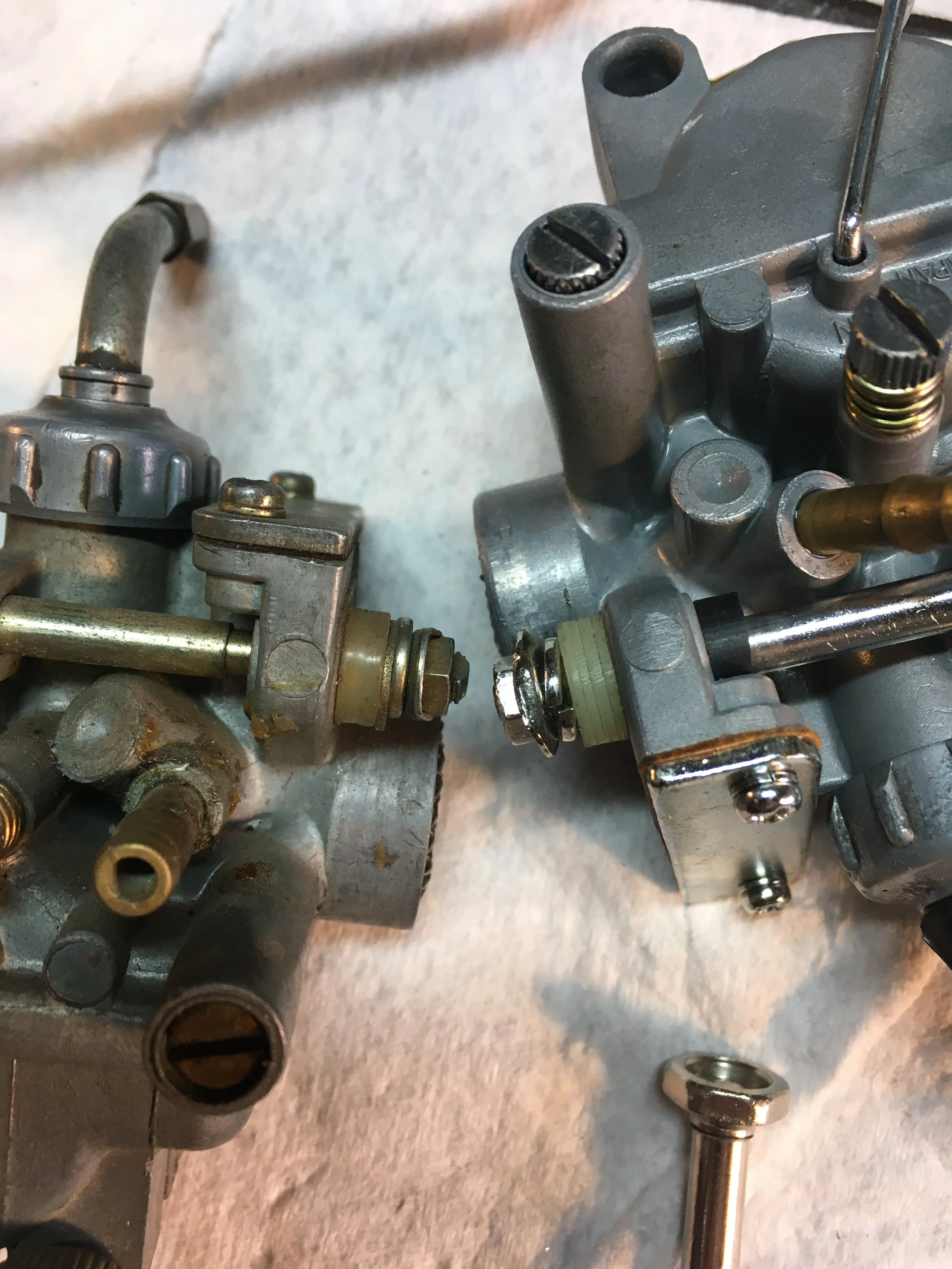

Awaiting an oil level decal, and a final coat of clear on the oil tank. The air filter assembly and rear brake plate are ready to go. The air cleaner is another item that was different on the multiple Tiger Cub models. This one was also used on some pre-unit bikes. There are at least three different types used, as far as I can tell.

Only a few of the black parts were painted: the headlight bucket, horn bracket, speedo mount, and oil tank. The powder coating was done by Triad Product finishing in Lewisville, Texas, and is the best job ever! Not just hyperbole, the masking was impeccable, there were no runs, sags or bare spots, and the thickness was just right. In the past, I have used the powder coating as a base coat, and cleared over it, but this job was so good there is no need. The difference between the powder and painted parts is indiscernible.

An example of the wiring harness condition. Poor connections were cleaned, and the wire ends were freshened and tinned with solder. Dielectric grease was used on unexposed terminals as well as the bullet wire connectors on the wiring harness.

The wheel assemblies were taken down completely. The hubs and rear brake plate were powder coated, all the bearings were replaced, and the fresh hardware to finish it off.

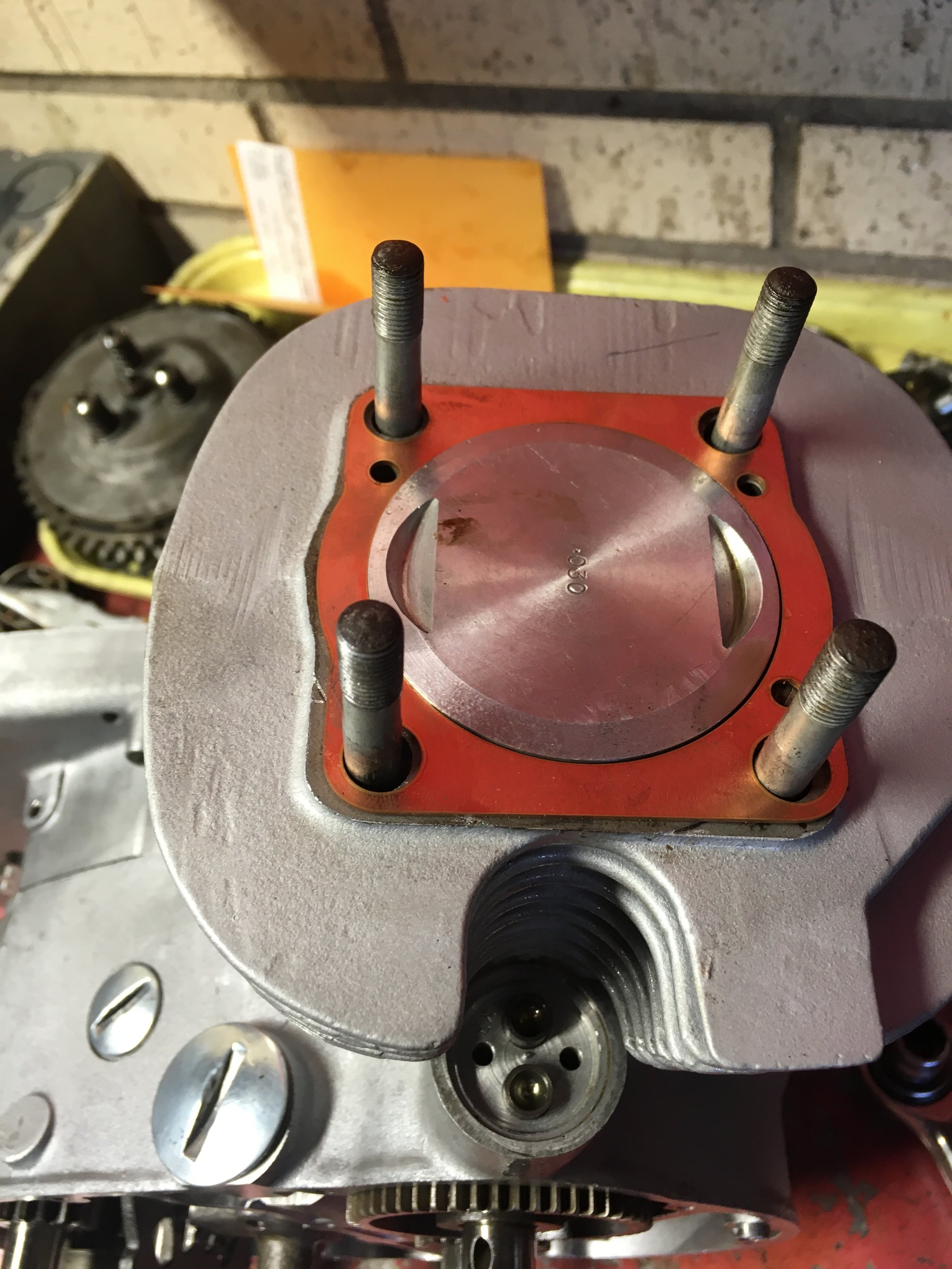

The thirty-over piston is in place with new gaskets. Still waiting on the head.

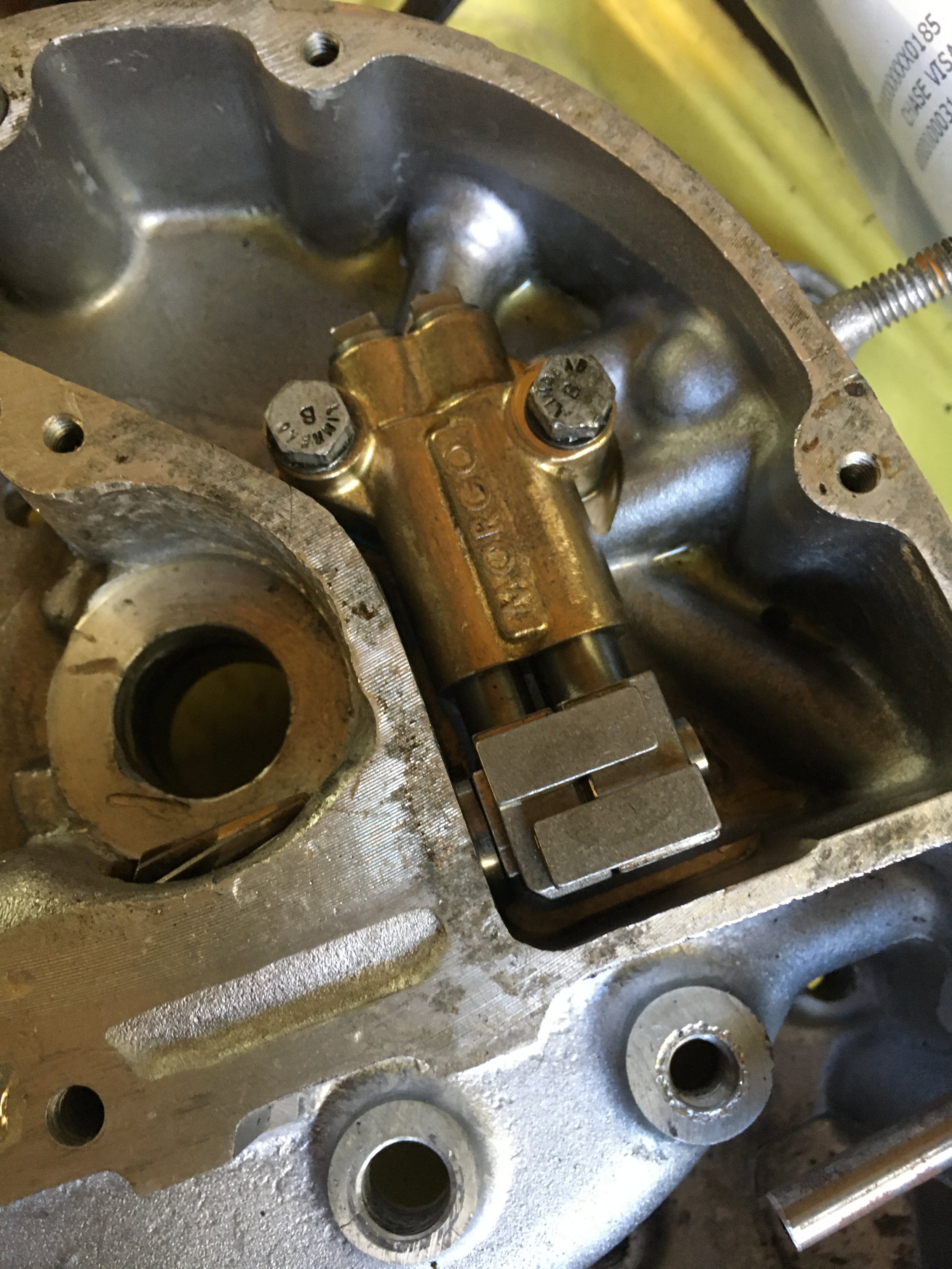

A transmission main shaft bushing is back ordered from the UK, and the right side covers can’t be put on without it. The rest of the engine block is assembled. The clutch hub bearings and rubber cushions were replaced. The primary drive installation is waiting on the transmission assembly.

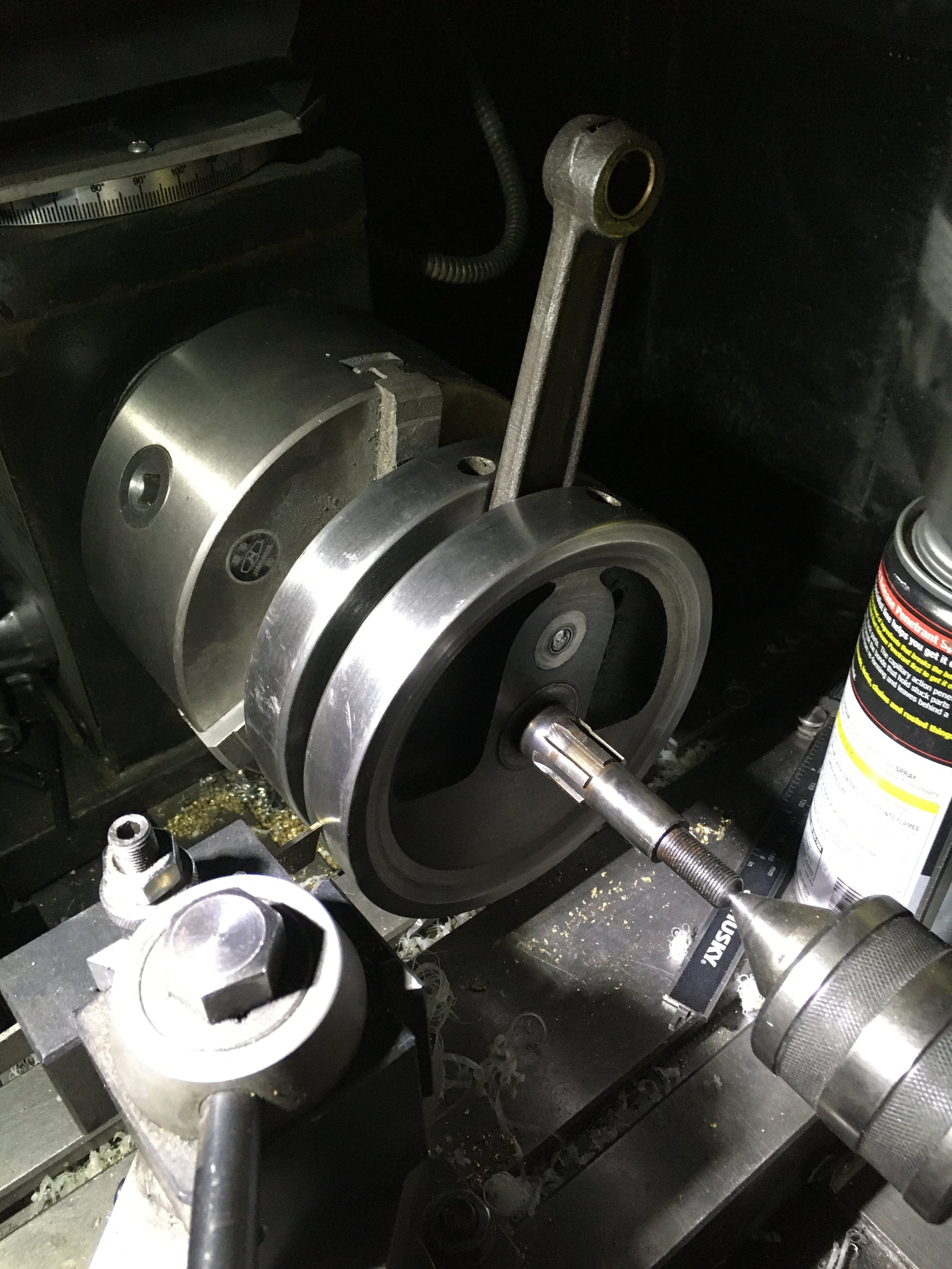

The crank shaft assembly was pressed together and then trued on a lathe. The roller bearing on the big end of the connecting rod ended up getting the nod after two successesive bronze bearings gave too much side play.

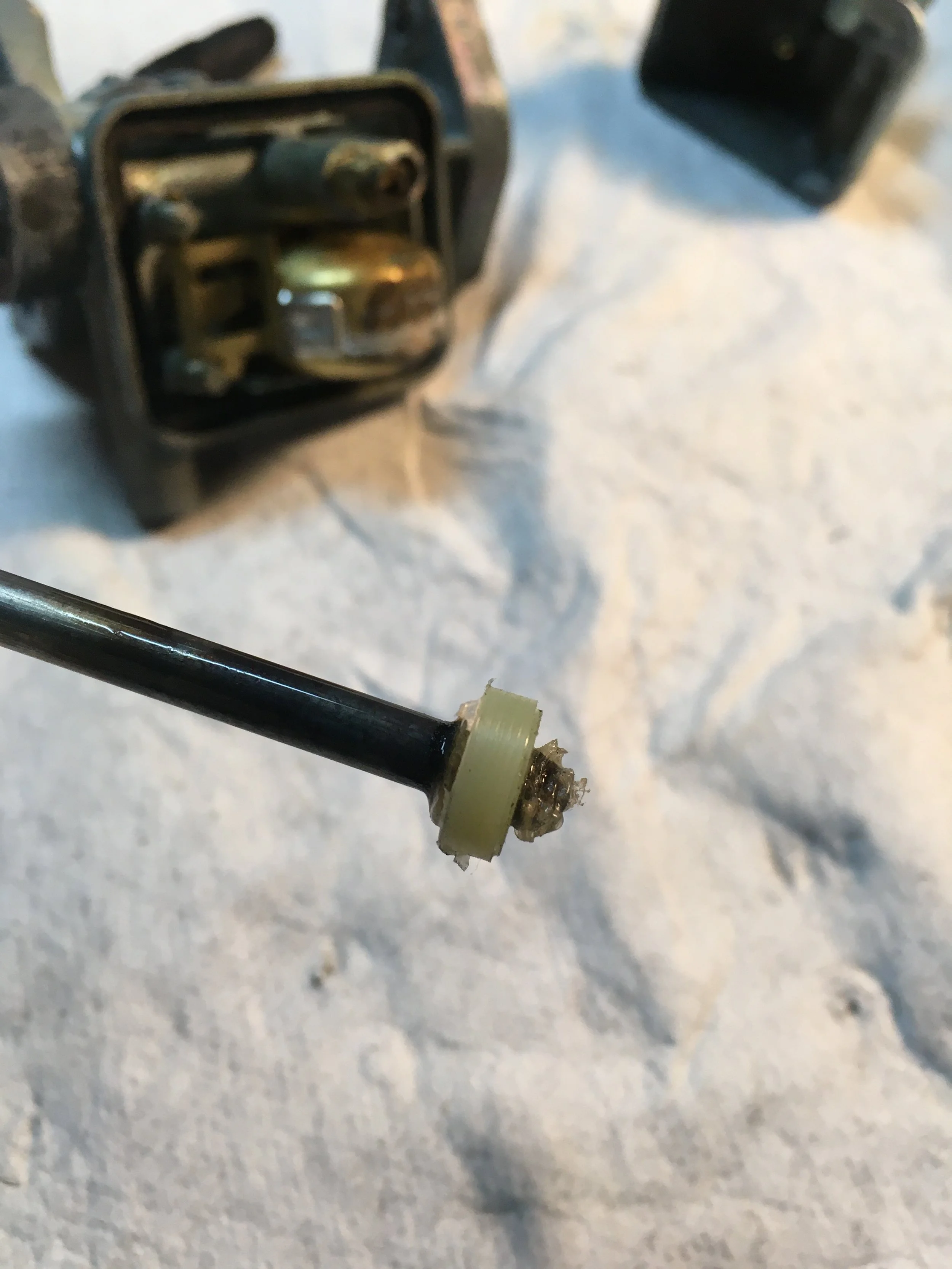

Making a rubber washer for the high beam indicator light, using an arbor press and punches.

And finally. My Buddy, Clinton rode up from Dallas, trying to get some miles on a fresh engine rebuild on his Norton Commando 850. Such a beautiful bike!