The Triumph Mountain Cub was a late sixties iteration of the Tiger Cub. The Tiger Cub, with 200cc’s was dubbed the “Baby Bonneville,” and was well received because it stayed within the 250cc limit for learners permits in England. It was produced from 1954-1968, with street or off road versions. The Mountain Cub was a US only model, produced in 1967 and 1968, intended to compete with small Japanese bikes in the consumer market. It was set up for street or off road, with some models including aluminum fenders, trial tires, tall bars, and stripped down so much there was no side or center stand. This particular Cub has MX-style high handlebars, knobby rear tire, folding pegs, deleted tach, passenger pegs and center stand, a high pipe, battery-less ignition, and a light front wheel with the small hub and an alloy shouldered rim. Not a bad start on an off-road set-up. The front tire, long seat, lights, and steel fenders, however, are more suited for street riding. It is not clear what parts of the bike are original factory parts, or those added by previous owners. The first order of business is to return the engine to original running condition.

Here it is, shortly after being pulled from the barn. A 1967 Triumph Mountain Cub motorcycle in Grenadier Red and White. This was a legacy bike, found by Skratch at Skratch’s Garage in Haltom City, Texas. The daughter of the owner wanted it to go to someone who was going to take care of it rather than flip it. That will certainly be the case. She asked for a chance to ride it again, once running. That is surely the intention, but as bad as it smokes, it needs tear-down and rebuild before it can be ridden.

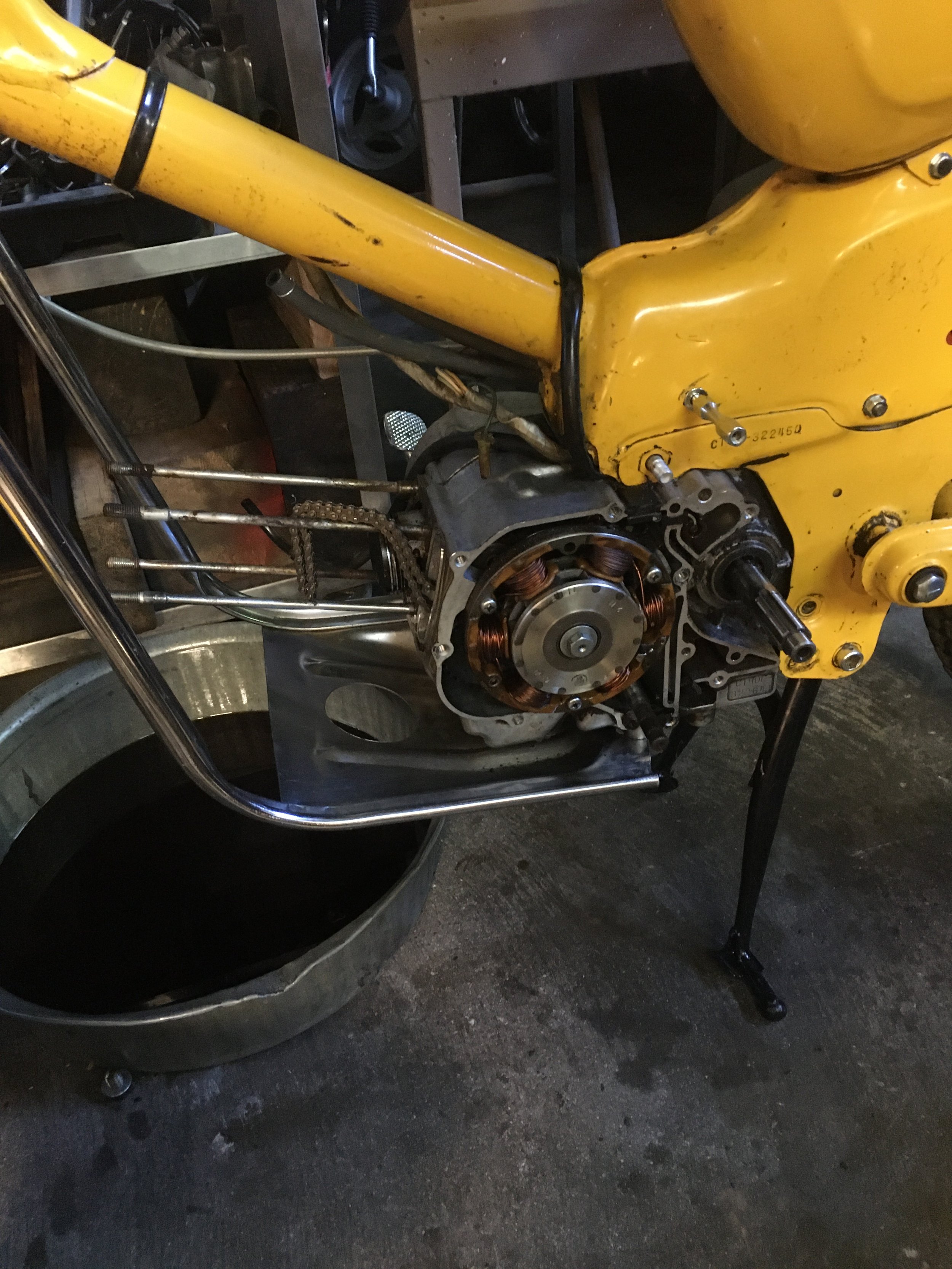

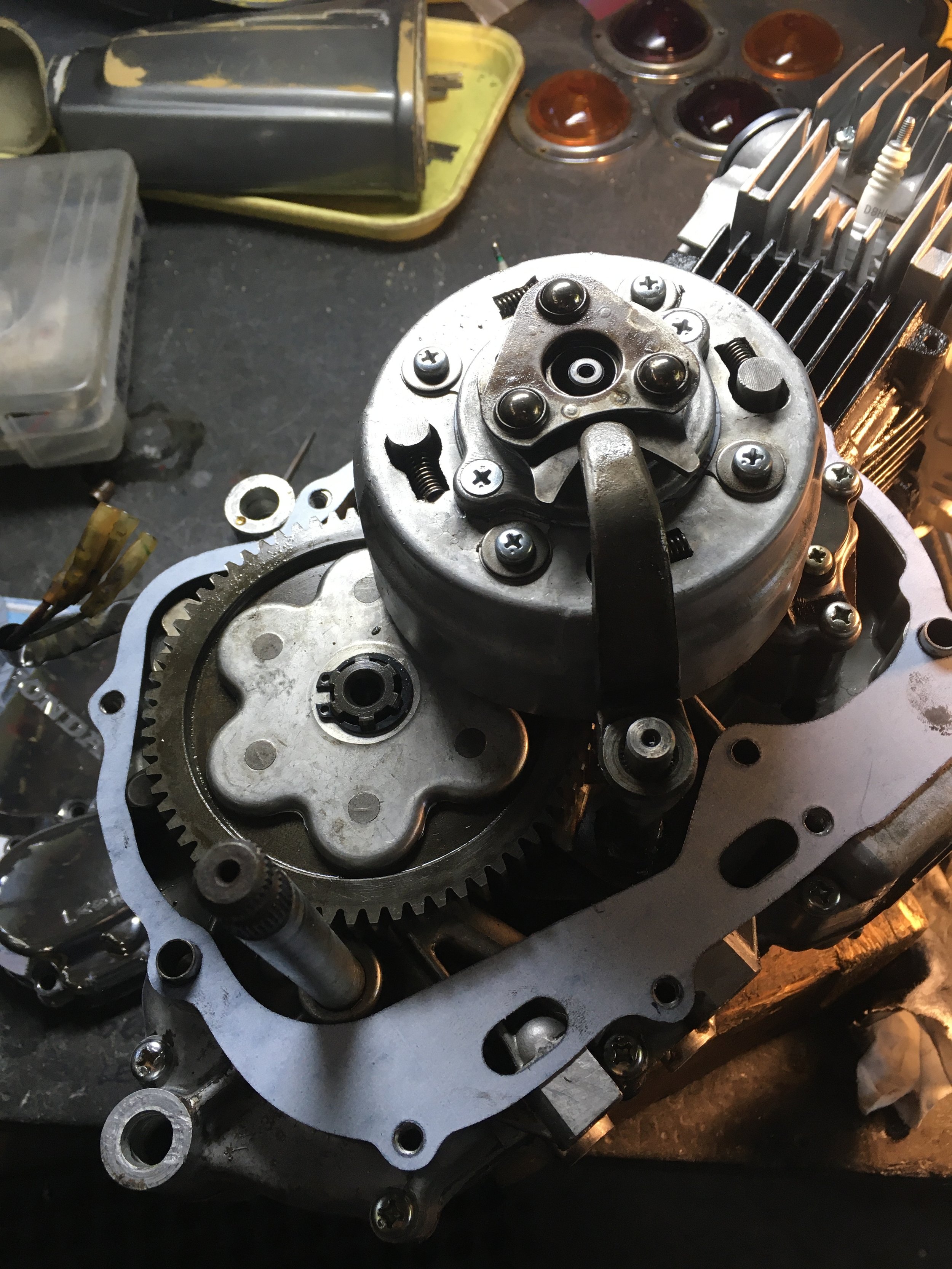

A number of changes had been made to the bike by the previous owner(s.) The exhaust had a section of flex pipe welded in the center, there were some dents, cracks, custom paint, and copious quantities of oil inside the muffler. The oil was from the engine, which smoked furiously, once started. The tank and carb cleaning were enough to revive it, but the smoking was bad enough I only kept it running a few minutes for fear of engine damage. The engine was wet-sumped, with a quart of the 1.5 liter capacity sitting in the engine. Even with it removed, the engine did no better.

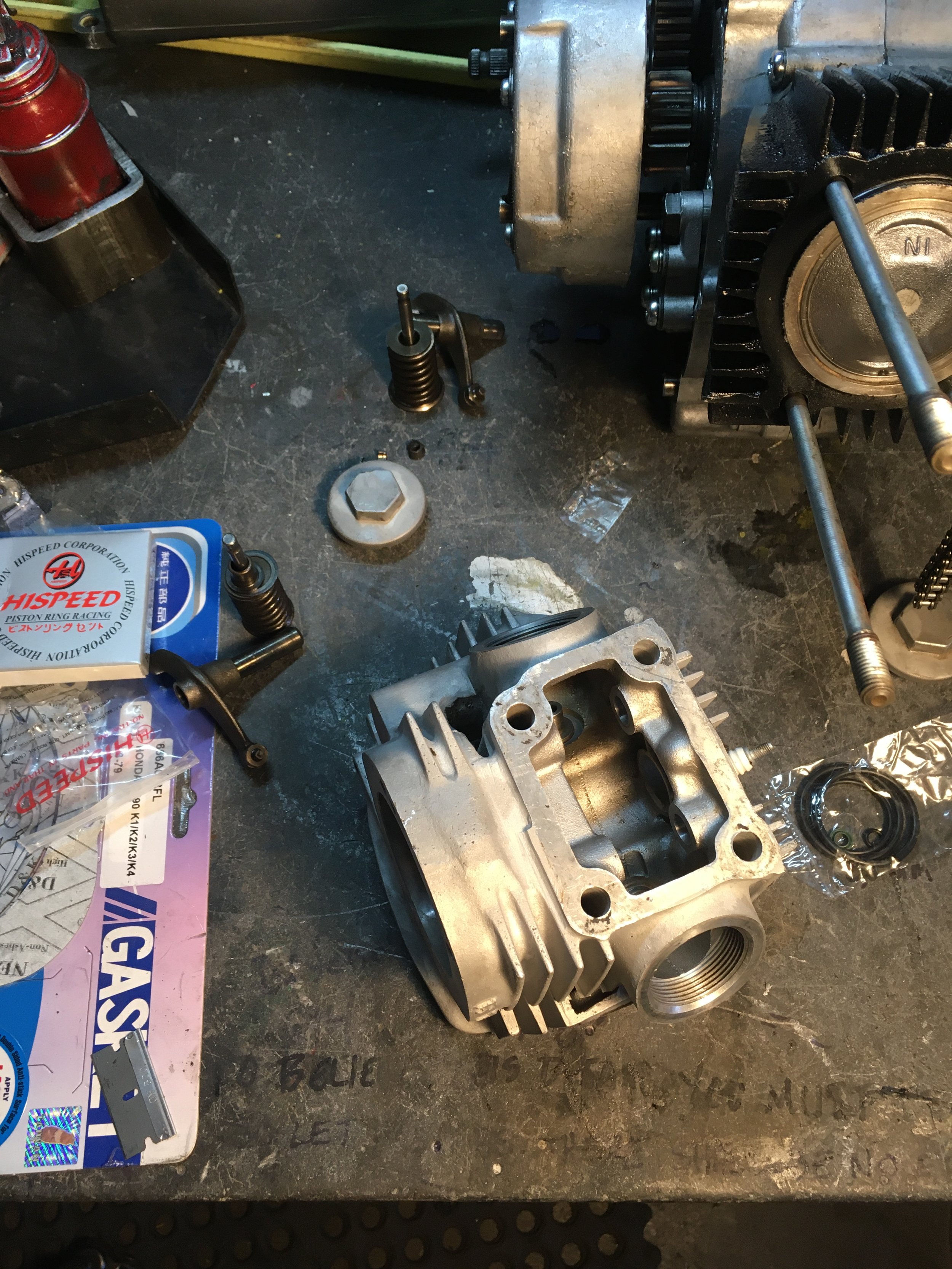

A couple of deep gouges were found on the side of the cylinder bore. A new .030 over piston and rings is on the way. It was easy to find higher compression (9:1) domed pistons, but the flat-top 7:1 CR pistons proved a little harder to find. Because these engines have a reputation for running hot, the lower compression piston was chosen.

Other creative changes made by a previous owner include remounting the speedo and horn on some hardware store brackets. I have my doubts this set-up was used, as the odometer is still set to zero. The speedo cable had been re-routed through the frame to make the cable reach, with a number of bends along the way. It has since been returned to the factory location along the bottom of the engine. The original 415 chain was hanging over the handlebars. A new Pro-Taper gold MX chain was purchased to replace it. New fork components are being gathered in preparations for a total rebuild.

Mmmm. Barn fresh. Mud dauber nests were fond in a number of locations on the bike. Pretty common in Texas.

Hard to believe a fuel system clean and some fresh oil is all it needed to run. The Lucas ET ignition does not require a battery, and starts the bike easily. The lights were operational, as are the brakes and clutch. The scavenging side of the oil system appears to be dry, with no significant oil being seen in the rockers. A new Morgo pump has been ordered to replace the original. All the passages and oil tank will be checked and cleaned.

The right side engine cover has a significant chunk out of the edge of the clutch adjuster inspection hole. A used one has been purchased to replace it.

The frames and tank on these models are unusual in the way the frame slopes down from the steering tube, and uses the tank as a stressed member. There are steel bars running through the inside of the tank, that have the external tank mounting tabs on each end, which bolt to the frame. This bike was designed by Edward Turner, accounting for some of the Bonneville-like styling.

After a bit of elbow great and some wrenching, the speedo is back to the original location, and the bars are a bit cleaner. The tank has been cleaned inside and out at this point, and is in good shape, overall. It will be repainted at some point. A new set of knee pads are on order. The front brake cable was repaired, and is operational now. The wiring for the kill switch and horn needs to be addressed, but there is likely to be some restoration done on the handlebars first.

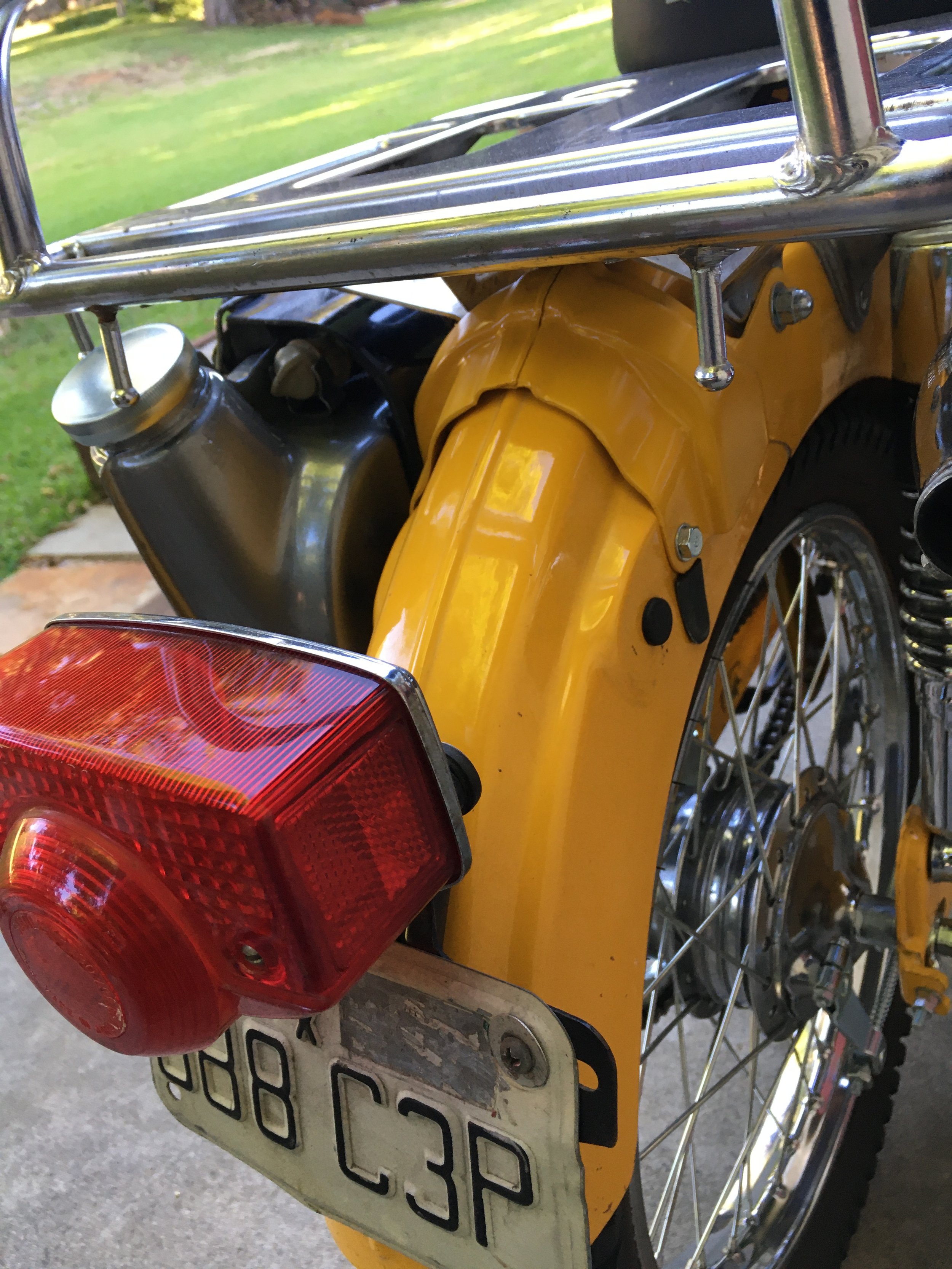

As cool as it looks at present, some custom touches are planned for the rebuild. The engine will be left mostly stock. The original seat is rock-hard and the plan is a shorter trials-type seat to replace it. The steel fenders may also get traded out for some alloy models, along with a smaller tail light assembly. The wheels will be rebuilt with rubber more suited for off road riding, and perhaps a rear alloy rim to match the front.

A new chrome plated exhaust system is on its way from England. Even though there were thoughts of just get the bike running, and leave it funky, there are enough things wrong with it that it has to go.

Just the clean-up and re-mounting the speedo return some of that classic Triumph styling.

I read that Gary Nixon won short-course races on a cub. Not planning to race this one, but a lighter race style looks great on this bike.

A skid plate was found online to replace the original one that was missing. Wear marks on the the oil feed pipes that rub the skidplate brackets indicate the bike was fitted with a skid plate previously.

Seems I can’t get away from UK brands. My buddy Peter, who has done the studio photos of my bikes, needed help on his 1979 MGB. The clutch had blown, and needed replacement. Here, I am feeling proud of getting the left motor mount on in ten minutes, after youtube videos said steering shaft and the whole rack and pinion rack needed to be removed to do the job ( it does not.) A lot of well-meaning people on there telling you how to get the job done like a total bung-hole. The solution is a slim 9/16” wrench with the nut and lock washer taped to it with gaff tape. The big flat washer that goes on before the nut and locker has to be put in place behind the mount first, but is easy to put in place because of the long slot the bolt passes through makes it easy to see and manipulate. The slim wrench and nut slipping by the shaft holds the flat washer in place