The Mountain Cub was broken down for restoration. Every part has been disassembled, cleaned, and inspected. New parts are trickling in. Mostly in a scattered state for now, with hardware out for cadmium plating, the head getting a rebuild, and the frame parts out for powder coating. A few aluminum parts have been polished, and dents were removed from the oil tank. There is always a learning process getting to know a particular bike. There is a lot of information available on the early years of the Cub, and more early used parts can be found as well. The information on the last two years of production (1966,1967) is scant, and things like the primary side cover are proving hard to find in good shape. The T20M Mountain Cub engine was produced during that last two years of the Tiger Cub run. There was a significant engine re-design in 1964 where the engine cases, crank, and side covers were modified enough that they are not interchangeable with later models. Other late model changes included a different connecting rod with a larger crank bearing and pin, something I found out disassembling the engine, as explained below.

The rust on the wheel hub was superficial, without any pitting, and cleaned up nicely after ultrasound degreasing and bead blasting. New bearings will go into the hub rebuild.

The frame parts all disassembled and degreased, awaiting bead blasting. Since acquiring an ultrasonic cleaner, the parts are cleaned in a water-based degreaser, opposed to the kerosene parts cleaner used in the past. The results are superior, and the process is less labor intensive.

The bead blasting is done, and any stubborn paint will be scraped or wire-brushed away prior to powder coating.

The factory brass-brazed frame joints are one of the cool things about Triumph frames. I have seen film of frames at the Meriden Triumph factory, where the frames are lying in a large bed of coals, being heated hot enough to apply the brass right there. While it seems a little crude, it is probably a pretty efficient way to get the job done. The frame was actually in very nice shape, without any significant alteration or distortion.

The crankshaft was disassembled, and it received a big-end roller-bearing conversion at some point. I have a new stock bearing and crank pin, but after disassembly, it seems the connecting rod is an early model with a small big-end bearing. A new rod has been ordered, with the bigger bearing found on the 1966-1967 engines. Given the copious smoke this engine produced when running, any non-stock parts are suspect as contributors, hence the conversion back to stock.

The sludge trap on Triumph cranks has always been a source of frustration. It is quite common for them to be badly chewed-up from previous removal (or perhaps, only attempts.) This one was no exception, and had to be drilled out. A 1/2” drill bit left just enough room to preserve the threads. This is the last little bit of the plug, wrapped around the drill bit. Fortunately, the threads were untouched during the process. Baxter Cycles had the new sludge trap replacement.

A couple of dents on the oil tank needed to be knocked out.

Some mandrels pressing the dents from inside of the tank through the filler hole, and a stud-gun to work out the rest, and its close enough for paint.

The replacement side cover was sanded and polished out. The case halves are clean, and all bushings and bearings have been replaced.

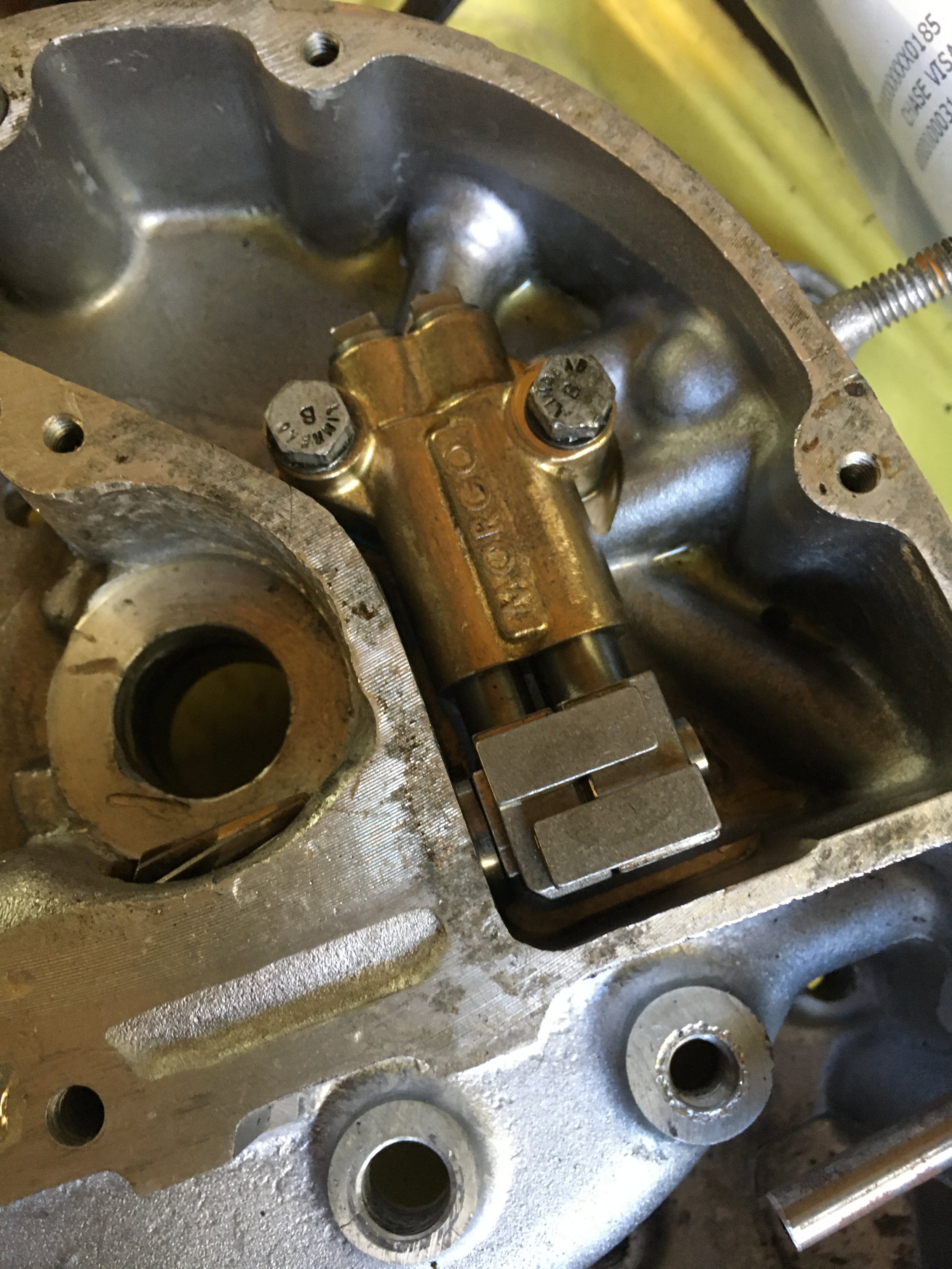

A new Morgo oil pump went in.Extra time was spent making sure that all the oil passages were super clean in the engine block, crank, and tubing, and especially the oil tank. There are many stories circulating amongst British bike owners about crankshafts and cams ruined after a rebuild because of a a dirty tank or sludge trap.

I left the head with Big D Cycles in Dallas, Texas, for new valve guides and valves. Once again, with everything else getting restored, and all the smoke it produced, it seems like it has to be done. This is the first time using an ultrasonic cleaner with a heavy-duty degreaser to clean parts. The finish was in surprisingly good shape on the engine center cases, given all the oxidation and wear on the side covers. There is a skid plate that goes on the bottom of the frame, and evidently it does a good job protecting the bottom (the thick layer of grease probably didn’t hurt either.) The new main bearings for the crank and tranny are in place, along with all the bronze bushings.

It’s a tedious process cleaning and working over the hardware prior to cadmium plating, but using the original hardware makes a big difference in the final product. Everything gets ultrasonic cleaning, degreasing, and wire brushing. Threads are chased and bends and nicks are repaired as well as possible Though there were some missing and incorrect pieces of hardware on the bike, a majority of the parts were there and in decent condition. The engine cheese-head Filson case screws had been boogered up a little, and were replaced with NOS ones. The heads of those original screws get hammered out enough to use again, but are still irregular enough to keep them out of this build. After all the prep, Texas Precision Plating in Garland, Texas does the cadmium plating.

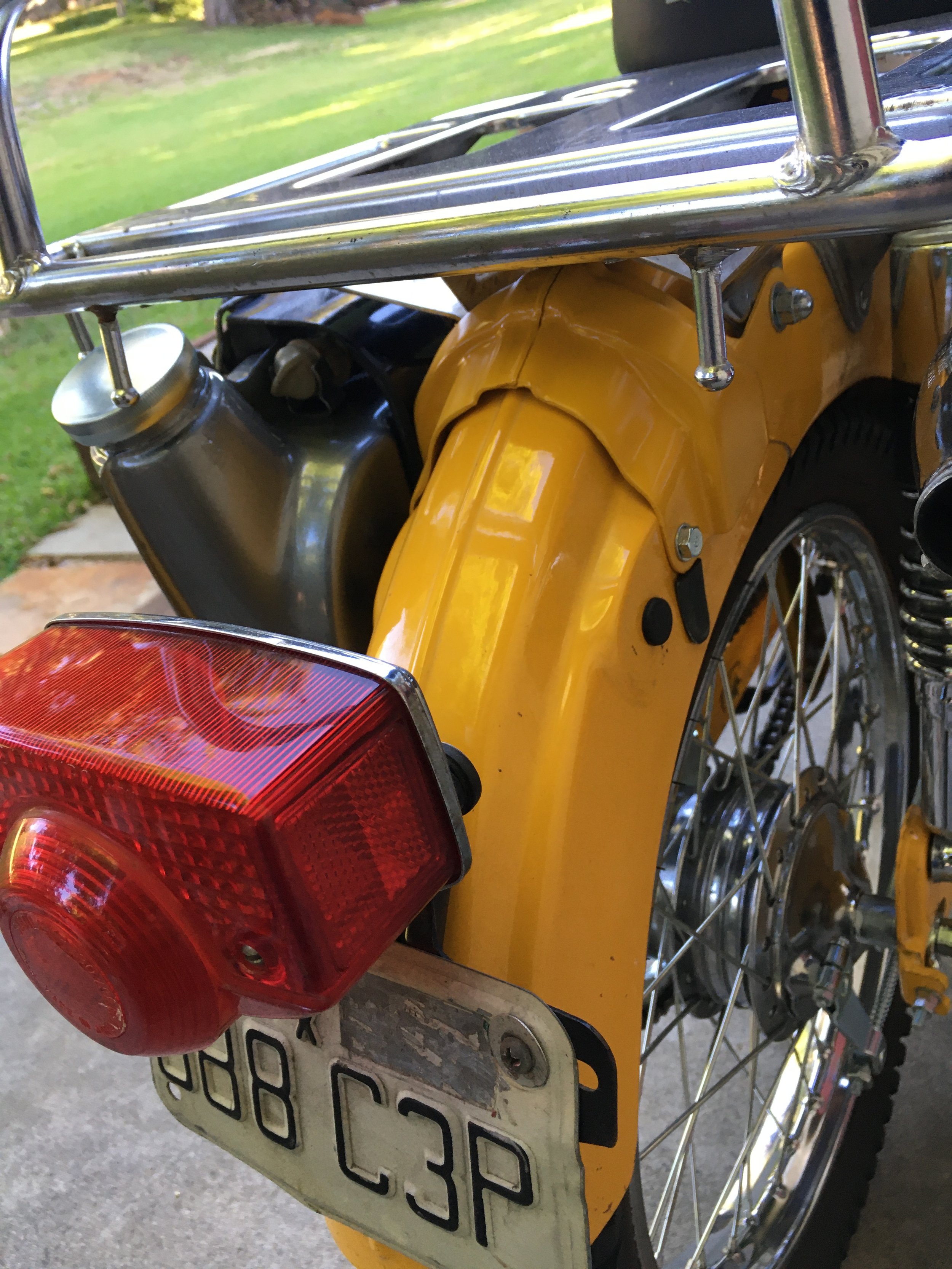

The passenger pegs were removed by a previous owner, so the brackets were trimmed off to finish the job. The lug for the kickstand was kept, and a dome from the rear of a Norton feathered frame finishes off the end of the tube. There will be a solo seat on this bike, so the rear pegs are not needed. A new location for the brake light switch will have to be worked out. The location for the switch down low on the frame seemed a little vulnerable anyway, and could benefit from relocation.

The original white steel fender on the bottom, and an aluminum one to replace it. The fender was a clearance model from Lowbrow, that was sitting on the shelf. A little hammering and English wheel, and the crown was raised to more closely match the deep original. When the bike starts to go back together, the plan is to make a custom aluminum front fender as well. The modifications to the bike are all reversible. The old seat, fenders and tail light will be preserved should anyone want to restore it to original in the future.

The splines on the gear shift shaft were a little hammered. They worked, but look like a future failure waiting to happen. Baxter Cycle had a replacement for three bills, seen on the right. I was thinking a single-cylinder restoration might be a little less expensive than a twin or triple, but so far, that is not the case. A new shifter pedal will be used to keep everything as tight as possible.

New fork uppers are going on the bike along with new chrome locking collars, seals, gaiters, and bronze bushings. The restrictor cones are also being replaced, leaving the fork lowers, upper beauty rings, and tripletrees as the only original parts. Aside from the engine, suspension is one of the areas that I like to get worked out as well as possible, as it make so much difference in handling and comfort, and ultimately, safety.